Advantages of the measures on line

Wave Wesstrom, Industry Manager Feeding and Drunk; Ferran Martínez, Product Manager of Analytical; and Oliver Reher, Product Manager of Discharge (

Nowadays, the directors of the plants of feeding confront to a lot of challenges at the same time that they have to ensure the quality of the product. Depending of the product, have to fulfil the requirements of the FDA (Food and Drug Administration), of the European Union and of other acronyms as for example cGMP, GFSI, ISO, HACCP, SQF, SID, etc. These regulations specify cuales are the ingredients to use, the specific reagents, the processes to be followed and the sanitary ware conditions.

The directors of plant also have to fulfil with the expectations of the consumer, keeping the properties of the product and guaranteeing a good flavour or the correct texture. For example, the value of pH in some products is critical, since this can affect to the flavour of the product, as well as to the own hygiene.

To part of the obvious requirements of alimentary hygiene and quality of product, other aims that the director of plant has to reach are:

- Detection of losses of product

- Control of the raw materials

- Reduction of the energetic consumption as for example, the consumption of water

- Need of operators and personnel of qualified maintenance

- Need to reduce the budgets in maintenance and operation

- Prepare and control the necessary documentation for internal and external auditss

Analysis of laboratory.

At present, the alimentary industry trusts the analyses of laboratory of samples taken of manual form to ensure the quality of the product in different points of the process. The technicians of laboratory take samples of periodic form that they are sent in the greater shortness to the laboratory to proceed to a fast ánalisis.

In what the personnel of plant receives the results, can proceed to realizar adjust them and necessary corrections to improve the control of his process, or realizar the maintenance required. The main problem to act according to the measures of laboratory, is that these do not realizar in real time, require a time of wait and can cause manual errors. If we need 30 minutes to take a sample and analyse it, the results obtained are representative of the process 30 minutes ago, no of the current process. This can repercutir in a batch in bad state.

In the case of the measures on line, is possible to detect a sudden variation of the process, allowing a fast action correctiva and saving like this the batch.

In this article, will show some examples of instrumentation that can use for the control of quality on line as I complement or replacement of his measures of laboratory, allowing like this immediate corrections of the process and automating the controls of quality of the product.

Analysers on line

The analysers on line do not fit in all the analytical measures of the alimentary industry, but yes that they can apply in many of the most common measures of laboratory. The table number 1 sample a listing of the typical measures realizar with this type of instruments.

Table 1: Measures of analytical on line

- Mass discharge for a correct control of recipes

- Density, Brix, Dish, Baumé, ˚SALT, degree of fermentation

- % concentration (solid, alcohol, etc.)

- pH (by means of sensors without glass)

- Viscosity

- Conductivity

- Oxygen dissolved

- Chlorine

- Turbidez

- Colour

- specific Gravity

Caudalímetro coriolis Installed in a bypass, like the Promass I of Endress+Hauser, for the measure of viscosity of a mass.

The use of analysers on line helps to optimise processes. For example, the quantity of desinfectante used in a hydro cooker for food enlatada has to be strictly contralada to fulfil the requirements of the alimentary hygiene, since an excessive dosage can cause the corrosion and the waste of the reagents, whereas an insufficient dosage can engage the alimentary hygiene. In a plant that previously supervised the quantity of desinfectante taking manual samples and realizar measured of laboratory, installed measured on line of free chlorine, pH and conductivity for the desinfectante. The measures in real time supposed an annual saving of 10.000 € in desinfectante when solving the problem of the dosage. These measures also allowed to the system of automation add water of contribution basing in the values measured, saving like this in power calorífica and consumption of water, and generating less waste water. Thanks to the measures on line, no longer was necessary to command to a technician of laboratory twice by hour to collect sample to process. The final result is a return of the investment in 7 months. We find a similar example of how the analysers on line can reduce the costs in a factory of cheese that realizar five CIPs by day. The reagents supposed a cost of 1.350 € by each drum of 113 litres and the plant used of 3 to 4 drums by month. The plant installed a sensor OUSAF11 for the detection of phases. By means of light UV and NIR, the sensor can detect the escapes of product, the changes of phase and realizar measures of turbidez or solids suspended. Detecting the separation of phases between serum, water and detergent CIP, the technicians of plant could determine when the rinse and the CIP had finalised, instead of depending on the measures of laboratory or to act by time. Thanks to this control, each cycle of cleaning CIP was reduced in 15 minutes and the plant save 32% in agents of cleaning. The saving was of 4.000 € the 3 first months, only in reagents, this without explaining the savings in power and water used. The plant also won in availability of the equipment of production, until 1 additional hour by day. Of course, the analysers on line are not something new. Many of these measures does years that use in the control of process. The main novelty is his greater reliability, to the equal that his new characteristic and capacities:

Reliability improved:

The experiences in the industrial world with the analysers are very diverse. Try apply analysers of laboratory directly in the process has comported some disappointments. Aggressive industrial cleanings, high temperatures, chemical agents corrosivos and other environingingmental factors often have caused the failure of the equipment and maintenances complicated. These problems have been solved rediseñando from zero the analysers and other equipment for measures on line.

Solid integration:

Traditionally, the instruments had of analog communication with an only exit 4-20 mA. Today, the possibility of digital communications like Ethernet/IP, Profibus, Foundation Fieldbus and Hart does that the integration of the team was much simpler. For example, a caudalímetro Coriolis measures the mass discharge, volumetric discharge, density, viscosity and temperature of process together with data of diagnostic through digital communications. These digital protocols also help to improve the accuracy of the team, deleting the conversions To/D and the losses of resolution of the signal of transmission in an analog signal 4-20 mA.

Calibrations simpler:

With the advances of the digital technology of the sensors, nowadays the laboratory can take the responsibility of the calibrations of the measures of the destined equipment to the control of quality on line. An example: in the past, to calibrate an electrode of pH was necessary to carry all the material (patterns, solutions of cleaning, a new electrode…) to the point of installation. Nowadays, the calibration of the electrode can realizar in the laboratory, in conditions controlled and the electrodes precalibrados are easily installed again in process. Endress+Hauser Memosens And other similar technologies do this possible for pH, oxygen dissolved, conductivity, turbidez, chlorine and other parameters.

Hygienic design:

One of the limitations of the monitoring on line has been the fault of instruments that satisfy the requirements of hygienic design and that they are resistant to the cleanings CIP and SIP. At present, the majority of equipment fulfil with the normative EHEDG and 3-To, and are totally designed for his use in the alimentary industry. An example of this are the measures of pH that the greater part of the people associates quickly with the sensors of glass. The glass represents a big problem in process, since the sensor can break and contaminate the final product. Nowadays they exist free reliable electrodes of glass that fulfil with the requirements of the alimentary industry. Caudalímetro coriolis That gives multiple measures of process. An only caudalímetro coriolis can measure several parameters simultaneously, deleting the need to incorporate different instruments, and with his high precision in the measure of mass discharge and of density (until 0,05% in the mass discharge and 0,0005 g/cm3 in the density) do to the coriolis ideal in a lot of applications of control of process. Often, to a lot of engineers of process overlooks them that, the own caudalímetro coriolis can be a good element to be used like control of quality of the final product. For example, the function of density can be used to measure directly degrees Brix or Dish, values that ensure the quality of the product produced. The option of viscosity, offers a measure in continuous to know if the product manufactured is inside specifications.

An alimentary factory installed a caudalímetro coriolis in a bypass of a line of mass. The mass was composed by flour, water and additives and had to achieve a suitable viscosity to be sent to another point of the process. The saving in ingredients, product refused and increase of quality of the product, made possible a return of the investment in the installation of this caudalímetro of less than 6 months.

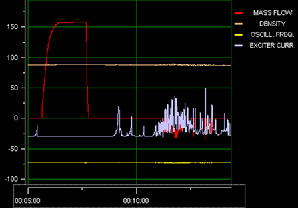

The diagnostics of the instrument verify the measures realizar alerting to the operator of conditions of process no usual. For example, the presence of air can cause problems in the process. An operator needs to know if there is presence of air because it is an indication of a bad estanqueidad of a board, or cavitación in a bomb, because the air can affect to the final quality of the product. A caudalímetro coriolis does not work well with big quantity of air, and his diagnostic has to detect this effect. In a caudalímetro coriolis of Endress+Hauser, the diagnostic has to verify that the tubes oscillate to a frequency of correct work indicating that there is not air. In case of presence of air the diagnostic has to change and indicate it.

The same function can use to increase the precision when it splits of empty pipe of product of process. The system of control can use the information of the diagnostic to act on the valve of control water down of the instrument to increase the contrapresión and delete the initial air, and afterwards gradually reduce the contrapresión to measure that the air goes deleting

The diagnostics in a caudalímetro coriolis can determine the presence of air in a liquid (purple line in the chart). This data can use like alarm of operator.

How begin

The first step would have to be evaluate all the measures that realizar in laboratory and determine which can be substituted by instrumentation of process. The aim is to help to the laboratory in the critical measures of quality, because the readings obtained by the instrumentation realizar in continuous. Considerations to take into account:

- How long invests in taking samples?

- How long employs in analysing the samples?

- How much personal occupies in these works?

- How long passes in the detection of a problem in the process?

- Which effect has on the costs of production this demora?

The application mentioned previously of the hydro cooker, is a good example of the saving of time in the taking of samples, and the saving of chemical product, when realizar these measures of analysis in continuous. The second question that could do us is: which instrumentation goes us to contribute really improvements in a process in particular?

For example, the measure of oxygen dissolved in a cervecera, wines or juices helps to minimise the oxidation of the product. The measure of degrees Brix in a sauce of tomato, can help us to determine the quantity of tomato to add. The measure of viscosity in a mass helps to determine the exact quantity of flour and water that has to mix.

The measures in continuous with analysers, can not substitute the work of laboratory in an alimentary industry, however this instrumentation can increase the efficiency and rapidity of the necessary information in the control of the process, optimising the quality of the final product.