Byg presents his new tooth with sole replaceable anti-wear

February 23, 2009

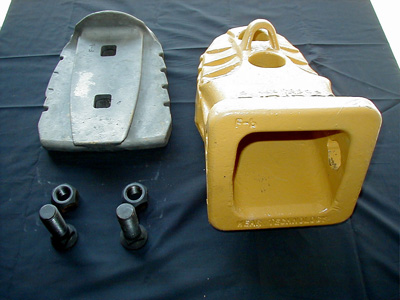

Unlike other existing on the market similar products, which are built in one piece, the tooth with sole replaceable wear consists of two pieces of different hardness: the upper part, or 'body', has a hardness of 500 HB and the bottom piece, or 'sole', which has a hardness of 700 HB, because that is the part subjected to a more hard work. Both pieces are assembled together securely via two locking screws.

Its novel design, with a controlled process of design, with study of alloys and a controlled production and heat treatment process, achieve greater durability of the tooth. This innovation achieves lengthen the life cycle of the tooth, reduce maintenance costs and increase performance and productivity, since the greater hardness of the 'sole' makes fewer replacements will be needed. The result is a more sustainable and compatible with any of the current systems of coupling and attachment to portadientes.

This new tooth is designed for extreme abrasion applications, especially for wheel loaders for mining or Rocky soils.

Design and quality of innovation

The two pieces, body and soles, fit perfectly with a recess in the side of each piece. The use of technology in 3D allows the design of Assembly models milimetrados, avoiding cracks.

The body and the previous piece are coupled through a few guides on tail of milano. The Union is reinforced by two screws and universal locking nuts. The tooth can be used in the portadientes by two systems: either through the washer and universal pin, with use of hammer, or by the nuevoconjunto of PIN and enroscable washer. This last method is faster and safe, is therefore done by manual, mechanical, without any other tools. The tooth sockets are designed to prevent instant and possible breakage.

With regard to the material used, the thorough study of the steel and its different alloys has obtained the most ideal combination so that the new tooth possess the mechanical properties necessary for the proper conduct of their duties, with the best performance and maximum service life. In our case, the combination of carbon, chromium, magnesium and Silicon you are granted the following properties: the chromium gives properties of anti-corrosion and less wear and tear; carbon and Silicon bring greater hardness; manganese provides greater resistance to impact.

The design and distribution of the different materials is as important as the alloy. So, has been used steel of 500 brinell for the body, which requires that the impact strength be increased to avoid breakage, and steel with 700 Brinell hardness of the sole, which provides strength to the tooth and abrasion resistance. The penetration is favoured also thanks to the design of the bottom of the tooth profile in grid and design in scales of the body, which promotes the flow of material.

Advantages of the system

The main problems posed by traditional tooth for wheel loaders is high wear to which they are subject and therefore their frequent replacement and its limited life cycle. The tooth with sole replaceable anti-wear offers an optimal solution to this problem. His design in two pieces allow replacing only the 'sole' of the tooth, which is the most affected part. This means substantial savings in the cost of the product, in the maintenance and the cost of recycling, reducing future debris for scrap.

Another advantage of this tooth is the guarantee for safe, easy and fast change. The tooth with sole anti-wear presents a study design that facilitates their handling in the substitutions, reducing the time of inactivity of the machine, which is an improvement on product with respect to the traditional teeth monopieza. Also, its simple Assembly mechanisms allow that changes are made easy, quickly and with less effort, which reduces the risk of accidents.

As advantage added to the cost savings, new Byg dandelion also favours an optimization in the use of raw materials. Handling, logistics and transport processes are also improved, due to the smaller size, portability and independence of the parts. Minimizing the volume of ferrous waste of product and reduces the costs of recycling, to discard only one of the pieces of the tooth, instead of the complete tooth in each change or substitution.

Also offers increased performance at lower cost, because the teeth traditional monopieza have a critical drawback: their limited degree of hardness. The incorporation of materials which provide a degree of higher hardness and the subsequent heat treatment necessary to pose an excessive cost of manufacturing costs. In the tooth with sole anti-wear, the use of a higher degree of hardness only in the sole reduces total wear of the tooth, increases your performance and allow their manufacture at a reasonable price, it is only one of the parties. While a hard monopieza tooth could be obtained with a special heat treatment, retrieved cost savings would never be achieved to do it in two pieces screw. It in a single piece of 700 HB instead of 500 HB would mean an excessive cost of production and also the degree of hardness of the upper part would be unnecessary.

The future wear line

The tooth with sole replaceable anti-wear RPHD that is submitted to contest, belongs to the Futura Byg line. It's a line of adaptable wear for earthmoving machinery. It is currently made up of 50 models of teeth and adaptive portadientes for Caterpillar, Esco, Hensley Parabolic, H & L, Komatsu, as well as teeth for mini excavators. The first six models were already set out in the previous edition of Intermat. In recent years he has completed the range and developed new models such as the one now presented. The innovative design of its teeth and portadientes lengthens the service life of the teeth and manages to double its effectiveness on the ground.

Features of the range

- Autoafilante design: Protuberans midrib and recess in the side which significantly lengthens the service life of the tooth.

- Autoafilante recess: stabilizer of the profile at the bottom that keeps the sharpening without reducing the resistance of the tooth.

- Lateral veins: to reinforce the safe and protect the bolt.

- Design in the form of scales that optimises the penetration and flow of material and improves performance.