Robotic applications in the fisheries sector

September 4, 2008

In this respect our point of view is so. There are procedures of work and very ingrained habits not for families may seem to us are equally effective. It is not easy, but no doubt a detailed analysis of these processes, together with a greater knowledge than the possibilities offered Robotics, would lead us to identify and refine implementation real niche. To endorse this idea and not remain in a purely theoretical level, we are going to give an example of a research project that tries to solve via robotics to a specific problem well known in the industry.

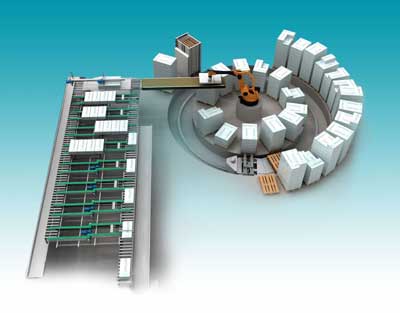

Project Storafish

The Consortium is composed of the Technological center of the sea (Cetmar), the technological center of automotive of Galicia (CTAG) and optimize Fodema, SA Brief analysis of the same notes the presence of two technological centres representative of two sectors as seemingly disparate as they are fishing and the automotive industry; two contrasting industrial fields where technological developments, and in particular the presence of robotic solutions, go clearly on the side of the second. Wants it to say that the link between these two centres (not limited to this project) is to create a channel to reach a technological shift of one other taking advantage of the experience accumulated by CTAG. This pairing is completed with the invaluable contribution of optimizing Fodema, S.A., a well established and known company that certifies a high expertise and a thorough knowledge of the sector.

Galicia in general, and particularly some of its ports as Vigo or Marín, host for years huge tonnages of frozen raw fruit of extractive fishing of high altitude. The availability of goods made possible the creation of an extensive network of cold stores that for logistical reasons tend to be located in the surroundings of ports or vicinity. The download process, either containers or from the cellar of the ships, is scarcely mechanized and involves the use of a very high labor; Despite this, it seems that the system has evolved in recent years.

We understand that the robotization applied to discharges, would involve a number of benefits, all of which are inherent in these systems in principle: pace of constant downloading, rationalization and lowering of the process and a substantial reduction in the employed labour force. The approach of Storafish stems from the conviction that it is feasible, from a theoretical and technical point of view mold a robotic structure and all your peripherals to the needs posed by this type of operation.

During the development of the project, which will be completed in the month of October, the virtual system has made it possible to visualize how this system behaves by changing working conditions and introducing therein all the possible variables (number of references)(size of the packaging, mosaics of palletizing, etc). In this way, you are identifying which are the existing limitations or other aspects to be considered expensive to design a hypothetical real model under a prior knowledge largely guaranteeing their proper functioning.

Real data

As for these, they are not completed, but what has been done so far suggest that robotic systems in these tasks would be feasible and absolutely preposterous. The transit between the theoretical and the practical seem affordable, especially when the conclusions of this work would pave the way and simplificarían it to rule out errors in design.

Unprecedented in Northern Europe

It remains to be seen if in coming years the application of Robotics is gaining ground in our industry. It would be desirable for the advantages of its implementation are obvious; They are not so the processes in which could be included, but the example of Storafish makes clear that there are scarcely mechanized procedures that could be overcome and made through these systems.

During the fair Conxemar, is more abundant information on the project at the stand of optimizing Fodema, S.A. In the same way, and that dissemination of results is concerned, dated 21 October will be held a day of presentation of results in Cetmar facilities. A specific website still in phase of creation will be available to complete the effort of the technological center of the sea by to publicize the work and the contents of the project, at the end of next month.