Waterproofing of foundations with synthetic sheets of PVC-P

December 3, 2009

Fields of application

These membranes can be applied to the foundation of slabs with vertical walls. In the foundation of slab system is composed of reinforced concrete, geotextile 500 GSM2 polypropylene, a membrane of PVC-P 2 mm thick, PE of 0.25 mm and concrete protection.

Elements referred to as 'water stops', supported by the presence of the installation of tubes of injection will be used as a system of control and repair. The surface in these cases must not exceed 100 m2 and 6 tubes of injection at least to ensure that the results are correct. Foundation slabs must be dealt with separately from the section of the walls by the entry of water.

On the vertical walls, they are composed of the following elements: conservation of the wall, layer of separation (example: 4 cm Styrofoam or similar), geotextile 500 GSM2 of polypropylene, PVC-P of 2.0 mm thick membrane, geotextile 500 GSM2 of polypropylene and concrete walls.

The same control and repair systems used in the Foundation slabs will be used. The water stops will be the elements that will make Union between the Foundation slabs and walls in vertical. The control surface is determined by in-situ.

Execution of the works

Concrete must pour after having completed the waterproofing system: the existence of a geotextile of PP of 500 g/m2 at a minimum, the membrane of PVC-P of 2.0 mm thick, a geotextile 500 GSM2 (or a sheet of PVC-P) as a layer of protection and will also recommend the installation of a sheet of PE on geotextile, in case that it is chosen as a layer of protection. Finally, it will get the layer of protection with concrete (approximately 7 cm).

The waterproofing system will take place on a slab in concrete, which will be able to connect it or merge it with the vertical walls. From that moment the walls will be built. This will happen in most of the sections, depending on the height thereof. After the work of the walls (concrete), the concrete of protection will be removed, thus the connection between the waterproofing of the slab of the system and the walls can be executed.

Waterproofing of foundations with synthetic sheets of PVC-P

The setting at the top of the wall can be enforced in various ways. One possibility is the installation of a 'stop water' on the upper side. After making the pavement with concrete, the scaffolding will be removed, the water stop will decontaminate, and is soldará then the same through hot air with the membrane, thus ensuring the tightness.

One of the most sensitive points in the tightness of this topology works will always be change between horizontal slab and the vertical wall. Local pressures on the corners will mean serious tensions have, therefore, it will be very important to run these areas with the greatest prudence.

Depending on the height of the building, the waterproofing system must be temporarily set to preserve the wall. After lifting it, fixing must be removed and the installation work may continue.

When continuing with the work of waterproofing, temporary setting will need to remove, and the next part of the waterproofing system is to be welded to the membrane already installed and placed on the surface in the next section in vertical.

Partitioning system

This system helps to strengthen the work of repair in the event of damage. With the help of the water stops soldiers to membranes a partitioning system shall be established. The surface of compartmentalization should not be greater than 100 m2. The water stops will be of polyvinyl chloride, and may be easily welded to the membrane. An automatic machine (for hot air) will be used to weld the 'water stops' on horizontal surfaces to membranes.

Water stops - Board expansion

The water stops will limit the extent of water infiltration. A system without 'water stops' there may be a point of exhaust with water penetration between the membrane and the concrete, as a result you will find the weakest spot 50 metres from the structure, thus failing the system. In this case, it will be very difficult to make any kind of repair.

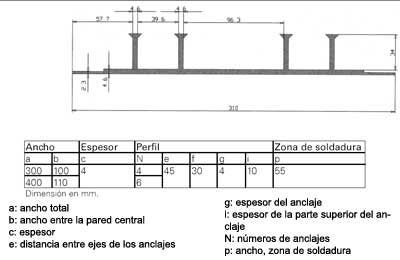

The 'stop water' divided the system of waterproofing with compartments. The anchors of the water stops must be integrated into the concrete to not allow that the water can be extended from a compartment to another. With these compartimentaciones water leaks can locate more accurately.

In addition to the 'water stops', is soldarán on time to the membrane called injection tubes. The task of these tubes will be given the possibility of injecting fluids to impermeabilizarán materials to thus be able to close the escape of the membrane. These fluids or resins are based mainly on two components, acrylic or polyurethane.

The work of injection is a very difficult task and must be implemented by expert staff. Resin injection should be pressed by injection tubes between the membrane inside the concrete. Very important is the mixture of resin, because as a component, the fluid should remain quite some time to to extend over the entire surface of the compartment on one side. On the other side you have to harden quickly so that it did not evacuate by water infiltration.