Solids Components Migsa, S.L. - Rotary valves

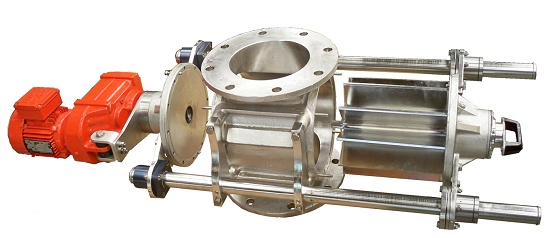

SRV Hygienic

Rotary presses valves: designed for the alimentary industry

Solids Components Migsa, with the aim to give answer to the increasingly demanding needs and specific of the alimentary sectors, chemist, chemist and cosmetic, offers his hygienic range of rotary presses valves.

This type of valves use for the extraction equipment equipment and dosage of products pulverulentos or granulated dry, stored to granel. Besides, said equipment fulfil the function of valve between two containers and his special design avoids that the material adhere in the element, when avoiding the edges in which this tends to hit .

The design of these rotary presses valves, allows the prevention of the microbial pollution of the alimentary products, fulfilling with the requests of alimentary hygiene of the corresponding rule of hygiene (CE Managerial 2006/42/CE of machinery, IN 1672-2 and IN ISO 14159 requirement of the hygiene) and the guidelines of the EHEDG (European Hygienic Engineering & Design Group) of which Migsa is member.

The model of rotary presses valve SRV Hygienic manufactures with the axis split for an easy cleaning of the interior of the valve (satisfied GMP-/FDA) and finishings and polishing mirror in surfaces that are in contact with the product.

Incidentally, this range of rotary presses valves Hygienic can supply like Element of hygiene (Protection System) according to ATEX 94/9/CE, and for zone 20 interior, zone 21 outside, with model certified by organism notified.

This type of valves use for the extraction equipment equipment and dosage of products pulverulentos or granulated dry, stored to granel. Besides, said equipment fulfil the function of valve between two containers and his special design avoids that the material adhere in the element, when avoiding the edges in which this tends to hit .

The design of these rotary presses valves, allows the prevention of the microbial pollution of the alimentary products, fulfilling with the requests of alimentary hygiene of the corresponding rule of hygiene (CE Managerial 2006/42/CE of machinery, IN 1672-2 and IN ISO 14159 requirement of the hygiene) and the guidelines of the EHEDG (European Hygienic Engineering & Design Group) of which Migsa is member.

The model of rotary presses valve SRV Hygienic manufactures with the axis split for an easy cleaning of the interior of the valve (satisfied GMP-/FDA) and finishings and polishing mirror in surfaces that are in contact with the product.

Incidentally, this range of rotary presses valves Hygienic can supply like Element of hygiene (Protection System) according to ATEX 94/9/CE, and for zone 20 interior, zone 21 outside, with model certified by organism notified.