Quality in the Union for welding process

Escola Tècnica Superior D'enginyeria Industrial de Terrassa (UPC-academic)

15/11/2003

Introduction

The standards UNE-EN-ISO 9001 and 9002 in clause 4.9 "Process Control", specify the following:

"The supplier must identify and plan the processes of manufacture, installation and after-sales service, which directly affect the quality, and must ensure that these processes are carried out under controlled conditions.""These controlled conditions must include the following:"

- the documented procedures that define the form of manufactured products, carry out installation and after-sales service, when the absence of these procedures could have an adverse effect on the quality;

- the use of appropriate equipment for production, installation and service after sales and adequate environmental working conditions;

- compliance with standards or codes of reference, the quality plans or documented procedures;

- the supervision and control of the appropriate parameters of the process and the characteristics of the product;

- where appropriate, the approval of the processes and equipment;

- the criteria for execution of work, which is should provide a more clear and practical way possible (for example, by written rules, representative samples or drawings) for

- "the proper maintenance of the equipment to ensure the continued ability of the process."

This clause generally speaks of a process of manufacturing, but a manufacturer within the process may have a part in which use welding.

If analyses this clause, you will see that while reasonable when not specified the procedure, if applied to a process of Union by welding, appear points with more than one interpretation. For example, the first paragraph to indicate processes that is should document, in the case of a process of Union by welding, this could be interpreted as the need to specify each welding in a piece. But this point can be solved if work is done by qualified welding procedures specifications.

Welding is a process where parameters that should be monitored to ensure the quality of the welding, can not be easily inspect and can become manifest only during the use of the product. It is difficult and expensive to check the properties of the material to be welded, metal welding and heat-affected zone. The processes that has these characteristics are called "special processes" in the ISO 9000 standard.

In principle, the ISO 9000, not describes us in detail the "special processes", which are processes in which the quality of the product is not guarantee fully with an inspection after the event. For example, welding even the non-destructive testing, cannot guarantee us that all the aspects that have a significant impact on the quality of welding have been correctly applied.

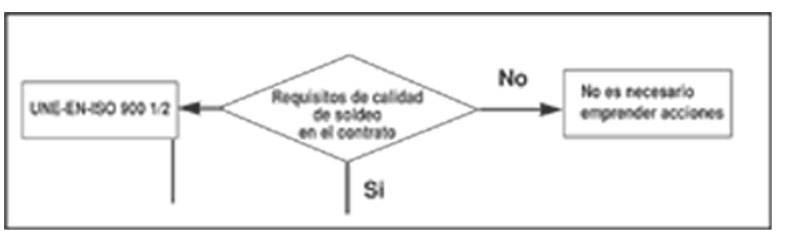

If the quality can not inspect a product, according to the UNE-EN-ISO 9000 has to be present to him [2]. The norm UNE-EN-ISO 9000 refers to the application of the standard UNE-EN 729 when there is the process of welding quality requirements. This rule can apply her both companies only involved in welding, such as companies that want to apply the standard of quality ISO and some part of the process there is a welding operation.

The technical standards Committee drafted the norm UNE-EN 729 "Quality requirements for welding" [1].

UNE-in-729 quality requirements for welding

- The UNE-EN 729 indicates the quality of the production of welding, not the design requirements.

- The UNE-EN 729 refers to processes of welding by fusion.

- The UNE-EN 729 makes no limitations in the materials.

- The UNE-EN 729 does not require any certification of the manufacturer. The demonstration that the manufacturer complies with this regulation could include the certification, but it is not any obligation.

- The UNE-EN 729 establishes the requirements for the equipment, personnel and welding procedures and us refers to specific standards which dealt with in more detail each of these aspects.

To ensure efficiency in a manufacturing process that involves some critical welding. Management or engineers must evaluate the sources of the problem and choose the appropriate quality procedure.

When should I apply the UNE-EN 729-2?

To ensure efficiency in a manufacturing process that involves some critical welding. Management or engineers must evaluate the sources of the problem and choose the appropriate quality procedure

In addition this standard refers to the specific rules dealing with each of the requirements of quality of a weld, see Figure 1.

The main requirements referred to in this regulation are:

1 Terminology and classification:

1.1. Terminology of welding.

1.2 Classification of materials, processes of welding, imperfections, etc.

1.3 Classification of consumables.

2. Design:

2.1. Design of welded joints.

2.2 Resistance and applicability of the welded joints.

2.3 Assessment of the adequacy to the service

2.4 Relating to imperfections in the welding quality requirements

3. Technology of welding:

3.1 Technology guidelines

4. Control of post welding heat treatment, welding, etc.:

4.1 Review of design and contract

4.2 Contract

4.3 Staff of welding and post welding heat treatment

4.4 Staff of inspection, testing and exams.

4.5 Equipment

4.6 Activities of welding

4.7. Welding consumables

4.8. Storage of the base material

4.9 Activities of post welding heat treatment.

4.10. Non-conformities and corrective actions.

4.11 Calibration

4.12 Identification and traceability

4.13 Records

5 Inspection and testing:

5.1. Destructive testing

5.2. Non-destructive testing

5.3 Methods of calibration

5.4. Metallographic examinations

5.5 Visual examination

5.6 Inspection of welding

Conclusion

The norm UNE-EN - 729 was developed to identify all the factors that can affect the quality of the welded product, which should be controlled before and during the welding process. The ISO 9000 requires that the control of the process is planned and implemented, but in the case of welding the UNE-EN 729 goes one step further and added that operators of welding must be duly qualified and taught by a supervisor competent in the type of welding that made.

Many of the elements found in the ISO 9000 for manufacturing processes in general, as for example the revision of the contract, the planning, review and maintenance of equipment, documentation of procedures, inspection sheets, calibration... are also the norm UNE-EN 729 but applied specifically to the welding processwith special emphasis on the critical elements for the quality of the weld.

The standard UNE-EN 729 part 2 requires the documentation of procedures and factors influencing the quality of the welding, for example procedures for welding, qualification of welders, certification of consumables, inspections, maintenance plans....

On the other hand, the ISO 9000 standard establishes that all procedures must be documented in detail and it must develop a quality manual. I.e. a manufacturer with products presenting a solder if it applies the standard UNE-EN 729-2 will be serving at the same time the ISO 9000 standard.

References

- Spanish Association of standardisation and certification (Madrid) "Welding: quality requirements". Madrid: AENOR, 2001

- José Luis Freire Santos, Roberto Díaz Alcover, Ignacio Zabala, Joaquin Rivera Ysasi-Ysasmendi "the new ISO 9000: 2000" Madrid. Foundation Confemetal 2001

- German Hernandez Riesco "Quality requirements for welded constructions". Metallurgy and electricity. April 1998