Policies and systems for recycling of plastics

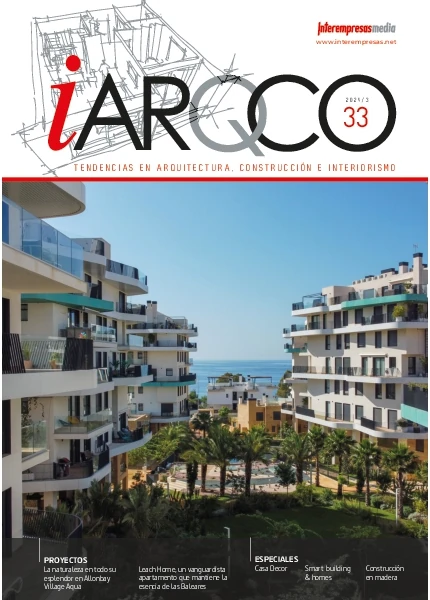

Figure 1 Some plímeros have a high value of recovery; in the U.S. a well organized collection of PET bottles makes it possible that, in the Virgin powder, 25% come from recycling.

Figure 1 Some plímeros have a high value of recovery; in the U.S. a well organized collection of PET bottles makes it possible that, in the Virgin powder, 25% come from recycling. The EU directive on packaging and packaging waste establishes specific targets within five years and obliges each country to take measures to ensure compliance. The main problem, in addition to mount the integrated management system - that carried it out the company Ecoembalages, created the effect-is there a universal solution for the issue of recycling of packaging waste. The most effective solution from an environmental and economic or integrated point of view depends on crowd of parárametros, which makes what is desirable in a place totally wrong in another, even within a geographic area.

The packaging and packaging waste directive aims to achieve a high level of protection of the environment from the field of packaging and waste. This objective is applicable to all types of packaging and waste put on the market, irrespective of the point in the chain that occur in, from the industry up to the final consumer. The only exception are production waste, as reminds Elena Ordozgoiti, AENOR.

The directive, which carries the number 94/62/EC of 20 December 1994, was approved by the European Parliament and the European Council under the procedure of consensus. The discrepancies between the two bodies forced to use for the first time this procedure. In the end, turned out a text actually agreed, in the sense that nobody likes all but accepted.

The directive was published in the journal of the European Communities (12) on 31 December 1994 and entered into force the same date. Member States have to transpose the directive until June 30 this year, at the latest. As of June 30, 1996 it is presumed the conformity with the text.

The environmental objectives of the directive could be expressed in form simplicada, says Elena Ordozgoiti, AENOR, as follows: aim is to reduce the problem to represent packaging waste, more effective is, quite simply, not make them. Now, if there are no more obliged to use some sort of container, we look for those materials that have some value when packaging already does not fulfil his function as such. If finally find it inevitable to eliminate waste, because they have no useful purpose, do it in the safe and responsible way possible.

The polluter pays, already expressed in 1975, principle also applies to packaging waste. This principle makes the cost of the disposal of the waste who generate so that effort is directed at you only reach the stage of final disposal materials and unavoidable packaging waste.

2. The necessary transposition.

Spain has not yet transposed the directive, despite the fact that the Ministry of public works, transport and environment (MOPTMA) and involved industry had agreed a legislative project in the form of Royal Decree Law early last summer.

A few days before the holidays in August 1995, however, the Ministry presided over by José Borrell introduced three substantial changes in the agreed draft, with a more restrictive and reglamentista result.

Innovations were, in essence, included in the integrated system of management of packaging waste, the requirement to take a reduction of 10% of the total weight of waste containers managed by the system in five years and, in the case of PVC, doubling the percentage. Also added a provision that considered containers in reference to the PVC, chlorinated as toxic and dangerous and required that incineration should be according to the legislation of these substances. And establishing a hierarchical systems of reduction and waste treatment, with preference for reuse on other systems.

CEOE (Spanish Confederation of business organizations) showed its firm rejection of these amendments because he believed that they could not be assumed by the packaging sector and were not included in the directive. Directive, in fact, sets minimum targets and gave the responsibility to implement the necessary mechanisms to reach every Member State. These mechanisms should be detailed in the transposition of the directive, and hence its importance.

Despite the opposition of the packaging sector to recent changes set forth in innumerable meetings during the last autumn and winter, the MOPTMA was determined to adopt the Decree of containers before elections. After weeks of tension, however, the Government of Felipe Gonzalez chose to transfer the item to the new Government that arose from the elections.

The Government formed by José María Aznar on May 6 will be responsible for approving the transposition. Prior to the call for elections, the party was prone to transpose the directive without many changes, but in recent weeks has avoided pronouncing on the subject.

3. The green dot.

In any case, the directive requires but it not transposed into Spanish law. What industry representatives complain is that, without law, not cannot be launched the integrated management system, the so-called also green dot. According to this system, all the companies that put a container in the Spanish market is bound to pay the proportionate share of the cost overrun representing collection on traditional collection.

In other words, the difference in cost between the traditional collection and the collection process, over the cost of material separation and recycling, will be paid by the company that put a container in the Spanish market, even though this company is not Spanish. In the end, it is clear that this surcharge pays the consumer of the product, that the producer will affect it your price.

While there is no law, the system cannot be put in Spain up and nobody is obliged to finance the system. The company to be created for the integrated system of management has already registered name of ecoembalaje, S.A. and the management of waste from plastic packaging carried it out Cicloplast (see the last number of Plastics universal).

The date on which the Government of the people's Party will propose the transposition of the directive is unknown but sources in the sector are difficult to make this year and considered realistic to take place the first months of 1997. This delay will be, according to different views expressed in this magazine, the harder that meet the objectives set in five years in the directive. Plastic universal has tried in recent weeks seeking Popular opinion of the parliamentary groups and Socialist, without success, and responsible for the MOPTMA unwilling to make declarations to be in functions.

4. Achievement of the objectives.

The European directive on packaging and packaging waste establishes a set of priority objectives:

-Firstly, reverse the current trend of generating more and more waste of packaging;

-Secondly, and following the community waste management strategy to the year 2000, setting out options for waste management: prevention, promotion of reuse and process assessment through systems of selective collection in origin; and,

-Thirdly, optimization of final disposal of non-reusable or non-recoverable waste methods.

The goals relating to the valuation involve achieve in five years, as it summarizes a document of the Spanish Foundation of the plastic for the protection of the environment:

-a minimum recovery of 50% by weight of packaging waste and

-a recycled at least 25% by weight of the totality of materials of containers which are part of packaging waste, with a minimum for each material of 15%.

These two basic objectives has made it necessary to address the design of what is known as the integrated management system that allows the management of urban solid waste from other perspectives. a study involving several business entities, regional administrations and local and business of waste management, with the result of a proposal for a mixed model of selective waste collection was carried out by the Institute Cerdà throughout 1993 and 1994.

5. The integrated management system.

The joint of integrated management system model incorporates two containers of home pick-up for the organic matter and the rest or rejection and a network of igloos for recyclable materials of different colors: green for glass, blue for the paper and cardboard and yellow to light such as plastics and bricks and metal containers.

In view of the Environment Foundation of plastics, this proposal of integrated management system poses with the necessary flexibility to allow for the adaptation to the characteristics of the municipality or area in question.

The system must, on the other hand, respond to the reality of the market to ensure that your application is optimal: minimizing costs, recovering the materials with quality adequate to the demands of the market, identifying and developing markets for these materials recovered with the greatest possible added value and high potential demand for output quantities increased secondary materials that will be generated andon the other hand, taking advantage of the facilities existing at the moment.

In the opinion of the Foundation, the rest or rejection management emphasizes the importance of implementing environmentally correct techniques: fragmented management that make it possible for secondary recovery of some materials such as sand for construction or low quality compost and optimized elimination of several fractions that allows a better energy recovery in the event that it is necessary.

The integrated management system of municipal solid waste with the model thus proposed is, in the opinion of the Foundation, economically viable, provided it meets organizational tools to ensure their proper functioning.

6. The situation in Spain.

Currently unknown exactly the amount of packaging placed on the market in Spain, which is what counts for purposes of the directive, and is even less known breakdown by material.

To remedy this lack of reliable data regards the sector of the plastics, the Fundación Española plastics and the environment has commissioned consultant Coopers & Lybrand a study to know exactly the situation with regard to volumes of packaging and current rates of recovery as a necessary step to evaluate the means that have to be put in place to achieve the objectives set out in the directive.

The study will be a white paper on the container and the packaging of plastic to publicize the asituación and strategies to follow. A study with similar objectives is also conducting Anarpla, recyclers Association. It is expected to end of this month of may are aware the first findings of two studies and the difficulty level of compliance with the directive.

Early estimates of the Foundation aim to is are currently recycling in Spain 10% of all materials and recovering energy from a maximum of 5%. To achieve the objectives of the directive, provisionally think the Foundation, it would be necessary to increase recycling in another 15% as a minimum and enhance energy recovery 20% more, in the case of not achieving higher recycling rates.

Other estimates indicate that in Spain are placed each year from 800,000 to 900,000 tons of plastic packaging. Confirm this amount, it would mean that about 150,000 tonnes per year of plastic packaging should be recycled to achieve the minimum target of 15% by weight of plastic packaging.

7. Sufficient recycling capacity.

The Spanish market of plastics, like many others, was especially protected during the Franco era and the protectionist measures did not disappear completely until about ten years ago. This protection of the internal market caused the raw materials were more expensive than in other European markets, with the result that the Spanish transformers found it profitable to recycle the material.

Protectionism Spanish, because it has had a positive side effect: our country has an important capacity of plastics recycling. Josep Prujà, Chairman of the Committee on the environment of the CEP (Centre Spanish of plastics), recognizes the existence of these Spanish recycling facilities is not due to environmental but purely economic reasons, but in any case, now come to the hair.

In Spain they are now recycling plastics from the remains of the transformers and packaging materials in construction and agriculture, as well as Germany. The Spanish situation is completely different from that of other European countries. While at France or Germany not existed previously recycling facilities not having economic motives, is has been due develop regulations of the integrated management system to promote them.

These special characteristics of Spain - and Italy - makes many experts consider as not suitable copy of schemes put in place in Germany or France. In addition, in the opinion of Josep Prujà, the evolution of the DKR system German and the French Valorplast induces to create reasonable doubt on its effectiveness in a country like Spain that already has a significant recycling industry.

The problem of the recycled applications.

Once you have recycled plastics waste, the main problem is to ensure an adequate and cost-effective use of the resulting product. There are applications that are insensitive to charges or the content of chlorine can be included, but in most cases, it becomes a constraint on its use or to dispose of waste in certain ways.

Systems in which these problems are not significant are hydrogenation and the use of the carbon contained in the manufacture of steel. However, the first can be considered only for transforming very high quantities of crushed waste, though not shortlisted, to obtain hydrocarbons returning into the circuits of transformation or fuels. We have no news that in our country yet the second is used and its profitability, on the other hand, still remains to be seen.

A recent study carried out by the Dutch manufacturers of plastic raw materials estimated that if the benefit of the environment must be maximised, the mechanical recycling can be used as maximum in the 13 to 18 per cent of plastic waste. This limit is due to the costs of collection and selection of pure raw material market demand and the relatively small number of applications of recycled polymers.

The Dutch study also concludes that, even with the maximum levels of chemical mechanical and recycled recycled more than 50% of the plastic waste should be incinerated to achieve at least the energy recovery. Incineration for energy is a system which, in some cases, is therefore essential to adopt to packaging waste.

In the case of Barcelona, the transformation of the RESU in compost would precise installation to serve a minimum of 25 Ha, with a transfer of trucks to the place, not isolated and near where could be, that it would create, say many experts, one major problem of who would solve. In this case, a pre-selection of the plastic between the RESU would economically absurd, what won't happen in towns under an agricultural component in your environment.

The presence of chlorine in PVC is not significant in urban waste, to be a small fraction of the content of common salt in the RESU, which can cause the same problems on a scale much larger and should be resolved with appropriate filters. Anyway, there is a process which recovers most valuable matter, chlorine, no other cost to the installation, it is auto-energético for large quantities of PVC.

There are two facilities in Andalusia to retrieve PE films for greenhouses. The problem is the profitability of the product, since it is contaminated with Earth and this affects marketing despite its low price. In the current machinery of high performance fabrication of film, the presence of impurities salda with team work stoppages that are more expensive than the savings in the cost of the material.

The ghost of the excess of availability of the material on the other hand, plans on Europe. It has been claimed that this year will have 400,000 tons of recycling that will not find a buyer.

9. Possible profitability applications.

Logically, the recovery of feeders and rechaces usually does not present any problem and mills have been developed for this whose noise level makes it possible to install online without affecting the working conditions.

Plastics hardly used preselection may make it users, since that would require a "plastic culture" that is clearly utopian. However, there are materials with a very high residual value, particularly PET soft drinks bottles, and in United States he returning to the Virgin material in percentages close to 25% of the sold pellets without affecting its quality. Separate bottles of PET of other materials can be made, therefore, profitable, if it is organized with adequate geographical coverage specific collection.

It is also profitable, because they are generally large workpieces, the recovery of the polycarbonate. When GE plastics scheduled recovery of plastics from the automobile identification, decided to use it to manufacture pallets for their own products. However, the availability of recycled PC was so low to meet their own needs was necessary to make a "razzia" throughout Europe buying old computers and phones. Currently, its manufacture of pallets have become a millionaire production, that the percentage of recycling is decreasing by failure.

In many other plastics, especially in the greater production, as the polyolefins, may have an excessive cost separation of other polymers and loads or other elements other than metals.

However, the application possibilities are very important: in fact, already occurs in urban furniture Madrid with mixed plastics and can have other major uses as noise barriers from motorways. Everything depends on, and ultimately the cost.

In Germany the use of these materials is subsidized so that it does not prevent this type of use. The money comes from a small fraction of which collects following law Töpfer (the rest is used for administrative costs), duty on every German with some 10,000 pesetas per year for the privilege of having voted. It is clear that it is an aspect which considers the proposed legislation and that manufacturers are not going to sacrifice a part of their margins to fulfill, so the consumer will be finally paying the cost.

One of the arguments quite used to denostar the use of thermoset composites has been its "impossibility" of recycling. France is partially solved the problem and Germany completely. Trucks equipped with windmills collected thermoset materials from waste, reduce its size and serve it manufacturers of SMC that they use them as load. A Spanish producer of SMC, Astar, also uses, and is probably, in phase of adaptation in the other producers.

Like many of today's problems, the end use of plastics waste depends on a complex political decision. In this case, the situation is complicated even more because there is not a universal solution. Depending on geographical location, socio-economic level and the type of plastic than other treatment can be better. What they are in agreement the experts is that life-cycle analysis is an appropriate model but can not generalziarse. Each case is different and the conclusions can be totally different with only modify a parameter.

Thus, for example, or clearly if it is more convenient to use returnable or single-use glass bottles. In places water shortage, we say, clean returnable containers can not be a suitable method. If the consumption and cleaning is done near the coast, it can be very convenient to use returnable containers, because it is not relevant to the cleaning water to acquire greater salinity if he goes then to the sea. Specialists in the environmental field are at least sure of one thing: that everything is relative.