This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

La instrucción de hormigón estructural EHE-08 y la sostenibilidadCriteria and methodologies

Ehe EHE-08 education and sustainability

October 15, 2009

The new instruction EHE-08 establishes criteria and methodologies that help effectively to achieve concrete structures that contribute to a better sustainability. This article, drawn up by the Association national of the industry of the precast concrete (

Andece), offers a detailed overview of this instruction, which integrates both economic, social and environmental aspects.

Sustainability is a global, non-specific concept of structures of concrete, which requires that a series of environmental, economic and social criteria are met. The contribution to the sustainability of structures of concrete depends on the fulfilment of criteria such as the rational use of the energy used (for the manufacture of construction products, both for the development of the implementation), the use of renewable resourcesthe use of recycled products and the minimization of the impacts on nature as a result of the implementation and the creation of healthy working areas.

Also, the project, implementation and maintenance of concrete structures can take into account other aspects as the amortization of initial impacts during the life of the structure, the optimization of the costs of maintenance, the incorporation of innovative techniques result in business r & d strategies, the continuous training of personnel involved in the various phases of the structure, or other aspects of an economic or social character.

Background

During recent years, the different social agents have been expressing a growing sensitivity aspects linked to the protection of the environment and the achievement of sustainable development. In this respect, far from considering the construction as an innocuous activity, public opinion tends to perceive it as one of the main factors that work together for the condition to the natural environment.

The sustainability of structures of concrete depends on the fulfilment of criteria such as the rational use of used energy, the use of recycled products and renewable resources and the minimization of the impacts on nature as a result of the implementation and the creation of healthy working areas

In the above context, it should be a reflection on the possible contribution to the sustainability of the activities of project and execution of concrete structures. In that regard, the new instruction EHE-08 collects the challenge raised from society, trying to lead a process of awareness of the officers involved and establishing criteria and methodologies that contribute effectively to achieve structures that best contribute to sustainability. EHE-08 therefore considers it necessary to focus the activity of design and construction of structures in a new framework to consider the economic, social and environmental aspects in a comprehensive manner.

The economic dimension of the activity linked to the concrete structures can be assessed from the following data for the year 2005, in which the billing of materials and products included in the EHE instruction-related industrial sectors amounted to some 16,400 EUR millionwhich was about 2% of GDP. The contribution of the cement sectors, of the prepared concrete and steel to this figure can rate at 19.2%; 32.2 per cent and 11.3 per cent, respectively. It should also take into account that the actual construction activity is not included in the above data.

On the other hand, it seems clear the effectiveness of the construction activity as a tool for the attention of social demands (shelter, health, education, etc.), as well as element of planning and structuring of the territory. In addition, the construction presents potential as 'environmental sink' so that, as it progresses the current technical knowledge, is allowed to increase the use of products directly recycled or made from industrial by-products, with the consequent favourable impact as activity side of recycling and sensitive to the concern about the massive consumption of natural resources.

Sustainability strategies

The concrete structural instruction EHE-08 represents the regulatory framework which lays down the requirements to be fulfilled of concrete structures to meet the requirements of structural safety and fire safety, as well as the protection of the environment.

The instruction is applicable to all the structures and elements of structural concrete, building or civil engineering, with a few exceptions (pipelines, dams or composite structures, among others).

Among the major innovations that picks up the new text with respect to the previous command (EHE-98) is the sustainable approach that takes on this and are summarized below:

- Incorporation of sustainability criteria in the project, implementation and maintenance of concrete structures.

- Recycling and reuse of waste (recycled aggregates or mineral additions from industrial by-products).

- Prevention of generation of impacts during the implementation, by promoting the use of best environmental practice.

- Establishment of a rate of contribution of the structure to sustainability.

In this previous context is which is part of the new instruction which, from an environmental point of view of sustainability, raises a set of strategies, about the following aspects.

Maintenance is a good way to prolong the useful life of the structure, with what the environmental costs are better distributed in time

Maintenance of structures

The first nod to sustainability is evident in article 1 'Object'. While the previous instruction field of application of the directive was restricted to the design, construction and control of concrete structures, the EHE-08 extends the scope including the maintenance of the structures, which it is addressed throughout the life of the structure.

Article 103 defines the maintenance of the structure as the set of activities necessary to ensure that the level of benefits for which has been projected not to decrease lifetime project below a certain threshold (mechanical resistance characteristics)(, durability, functionality and, where appropriate, aesthetics). To do this, after the entry into service of the structure, property must schedule and carry out peacekeeping activities listed in this article, so the project of all types of structures will include a Plan of inspection and maintenance, that defines the actions to develop throughout the service life:

- Critical points of the structure specified special attention for the purpose of inspection and maintenance.

- Periodicity of inspections.

- Auxiliary means for access to different areas of the structure, if necessary.

- Techniques and recommended inspection criteria.

Maintenance is an activity of a preventive nature, which prevents or delays the appearance of problems who otherwise would have a more complicated resolution and a much higher economic level. Maintenance is a good way to prolong the useful life of the structure, with what environmental costs due to the action of building structure and manufacture products that are placed in it will be better distributed over time.

The best sustainable strategy is the use fewer resources to get the same final results

Hallmarks of quality officially recognised (DOR)

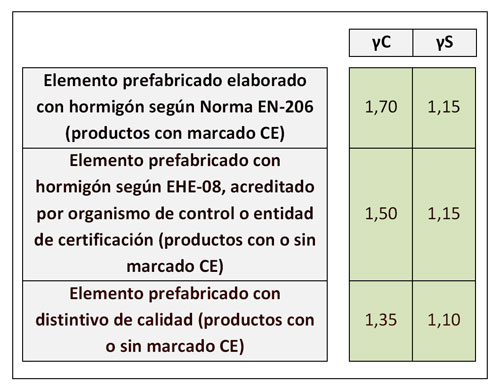

Possibly the best sustainable strategy be to use fewer resources to get the same final results. In this sense, the EHE set about reducing coefficients of the strength of materials (steel and concrete), which have a direct impact on having to employ a greater or lesser number of material to meet the basic demands of the structure (see table 1).

Table 1.

Here the use of products with the DOR, because it involves the use of punitive coefficients lower, with the consequent optimization of structural sections and a lower consumption of materials, factors that will benefit manufacturers acquire special relevance, prescribers and, in general terms, the society as a whole.

To obtain the DOR (annex 19), the instruction establishes a series of requirements to be met, in our case, the manufacturer of prefabricated structural, and that they must be verified by an external body that certifies its compliance. Among these requirements is that the manufacturer must have his registered quality management system according to the UNE-EN-ISO 9001, as well as a set of specifications for the materials used and their facilities.

Only 14% of the pathologies of the structures are due to failure of materials, compared to 48 per cent from errors in projects

Production control

According to data managed by the Permanent Commission of the concrete, only 14% of pathologies of the structures were due to failures of material compared to 48 per cent from errors in projects, and yet the number of checks and tests carried out on industrial processes always have been much higher.

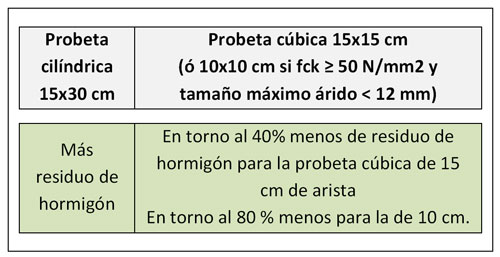

The new EHE aims to correct this situation by allowing to reduce the number of trials in certain cases, without affecting the quality of structures, as it is considered that, mainly due to the possession of the CE marking of many of the products involvedThese minimum security is guaranteed and disclaims the client's further trials. The EHE also contemplates the possibility that the manufacturer can be used for the determination of the compressive strength of concrete, cubic test-tubes instead of the traditional cylindrical test tubes (article 86.3.2.). This fact, a priori irrelevant, has a clear justification is the reduce the number of waste concrete and sulphur.

Table 2.

It also allows cutting sulfur mortar a single face, provided that compliance with certain conditions of surface flatness and symmetry. Only in 2004 broke down 6.5 million test tubes, which generated 82,000 tonnes of waste, of which 925 were mortar of sulfur (highly polluting product).

Consumption of materials

EHE-08 allows and encourages the use of more environmentally friendly materials with the environment. The new instruction, in its article 77.2 identifies a set of criteria that allow any of the different agents (maker, Builder or project management) differentiate between those products which may have higher values added from an environmental point of view:

- Durable materials.

- Materials with low maintenance.

- Simple materials, preferably of a single component.

- Easy to put in work materials.

- Recyclable materials.

- Efficient material energy.

- Healthy materials, both for staff during implementation, as for users.

In general, a structure has more value for the purpose of sustainability when it is compatible the requirements set out in article 5 of the instruction with:

- The optimization of the consumption of materials, using smaller amounts of concrete and Rebar.

- The use of cement or that incorporate industrial by-products, such as the additions.

- Supported by the existing regulations minerals, or that they obtained through processes that incorporate raw materials that produce fewer emissions of CO2 into the atmosphere, or obtained through processes that consume less energy, particularly through the use of alternative fuels to other primary fuel savings and the recovery of waste.

- The use of aggregates from recycling processes.

- The use of water recycled on the own floor of manufacture of concrete.

- The use of steels: coming from the recycling of ferrous waste (scrap), or obtained through processes that produce lower emissions of CO2 into the atmosphere, or to show a use their waste as, for example, of its slag, or coming from processes to ensure that the use of ferrous raw not radiologically contaminated.

Recycled aggregates

The annexed 15 develops specifications for the use of recycled aggregates, meaning the concrete manufactured with arid thick from the pounding of concrete waste recycling. Dry recycling can be used both for concrete in mass as reinforced concrete resistance feature no more than 40 N/mm2, being excluded its use in prestressed concrete.

For its application in structural concrete, this annex recommends limiting the content of dry bulk recycling to 20% by weight on the total contents of dry bulk. With this limitation, the final properties of the recycled concrete as soon as they are affected in relation to which presents a conventional concrete, being necessary for higher rates, carrying out specific studies and further experimentation in each application.

Indications on some of the properties of the concrete may be affected with more than the indicated limit replacements are given in the annex. In the case of non-structural concrete (annex 18) can be used up to 100% of concrete with recycled aggregates.

Article 27 of the instruction provides for the possibility of using recycled water from the washing of tanks in the own central of concreting

Recycled water

Article 27 provides for the possibility of using recycled water from the washing of tanks own concreting plant, where they met the specifications set out in this article. These waters are verterán on areas specific, waterproof and properly marked, and can thus be reused as water for the manufacture of concrete.

Good environmental practices

Aware that it is the first time that the EHE captures these themes in order to facilitate its implementation and environmental, the new instruction also includes a list of what is called "good environmental practices for the implementation" as defined in article 77.3.

- Be monitored than all of the personnel and subcontracting of work comply with the environmental requirements defined by the constructor.

- The environmental criteria in the contract with the subcontractors, defining the responsibilities that should be held criminally in the case of non-compliance will be included.

- It will focus on the minimization of waste, promoting reuse and, if necessary, the management of waste storages.

- It will plan since the beginning of the work, the hiring of a Manager authorised for the collection of waste in order to avoid unnecessary storage.

- You will be managed adequately the energy consumption of the work, ensuring the recruitment of systems of measurement of consumption that reveal these as soon as, avoiding also the use of generators causing a greater environmental impact.

- In the case of recourse to the demolition of any part of the work, it should be made using criteria of deconstruction that favour the classification of the relevant waste, thus promoting their subsequent recycling.

- Efforts will be made to minimize the consumption of fuel by limiting

the speed of the machinery and elements of transport for the

work, carried out through the promotion and adequate maintenance of the

use of low consumption vehicles.

- Will prevent the deterioration

of the materials contained in paper bags, for example the

cement, through a system of storage below deck to prevent

the weathering and further processing in waste.

- The pieces that make up the formwork will be properly managed and

the shoring systems, avoiding that subsequent operations of the machinery of

land movement, finally incorporated them into the soil.

- Is will have stocks in the work in such a way that they are used as before

possible and located with the greater proximity to areas where they are to

used in the work.

- Efforts will be made to the Assembly of the

Armor is carried out in specific areas to prevent the emergence

uncontrolled of wires in the parameters of the concrete element

corresponding with the funds of formwork.

Rate of contribution of the structure to the sustainability

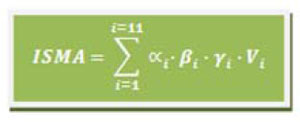

Finally, the EHE-08 defined in annex 13 a calculation model that allows quantitatively assessing the contribution of the structure to meet the criteria for sustainability. To this end, two indices have been developed:

- Index of environmental sensitivity (Isma).

- Contribution of the structure to the sustainability index (Ices).

This is in both cases of parameters likely to be computed by simple procedures from the conditions provided for in the project and developed during the implementation phase of the works. Its implementation is voluntary, unless the property otherwise. In this case, the property must communicate to the author of the project the level of sensitivity that, depending on the value of the Ices, must comply with the structure to incorporate appropriate measures in the draft. In addition, property should consider him in charged with the implementation, monitoring their compliance with the Builder and ensure that are passed on to users, if necessary, the appropriate criteria for maintenance.

Index of environmental sensitivity (Isma)

It is defined as 'environmental sensitivity index' of a structure to the result of applying the following expression:

AI, bi, gi and Vi are weighting coefficients, defined in the tables of the annex, and who value the contribution to the sustainability of eleven factors:

- Environmental characteristics of the concrete.

- Environmental characteristics of the armor.

- Optimization of the Assembly of the elements.

- Environmental optimization of steel.

- Level of control over the implementation.

- Use of recycled aggregates.

- Optimization of cement.

- Optimization of concrete.

- Specific measures for control of the impacts.

- Specific measures to manage waste.

- Specific measures to manage the water.

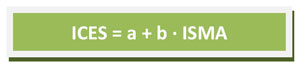

Contribution of the structure to the sustainability index (Ices)

It is defined as 'he index of contribution of the structure to sustainability' (Ices) to the result of applying the following expression:

having met, moreover, that:

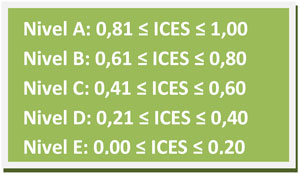

Where it is the coefficient of social contribution and b is the coefficient of contribution by extension of the useful life. From the Ices, can qualify the contribution of the structure to sustainability, according to the following levels:

Where it is the maximum end of the scale (maximum contribution to sustainability) and E is the extreme minimum thereof (minimum contribution to sustainability).

Related Companies or Entities

Asociación Nacional de La Industria del Prefabricado de Hormigón