Fire safety of the products of the construction in the European Union

Member of the Commission 23 "fire safety" of Aenor01/08/2006

Hygiene, health and environment. The construction products should not pose a threat to the hygiene or health of the occupants and neighbors for acts such as the release of toxic gases or hazardous gases, particles, the emission of radiation, pollution or contamination of water or soildefects in the evacuation of water, smoke and debris, and the presence of moisture.

Security of use: absence of unacceptable risks of accidents such as slips, falls, crashes, burns and electrocuciones.

Protection against noise: the noise perceived by the occupants or the people who are coming should be at a level such that their health is not threatened and to enable them to sleep, rest and work in satisfactory conditions.

Energy saving and thermal insulation: heating, cooling and ventilation installations must be constructed so that the energy consumption required for the use of the work is moderate taking into account local climatic conditions and without conflict with the required thermal comfort of occupants.

Fire safety: the work must be constructed so that its stability is guaranteed for a period of time, that the causes of emergence and spread of fire and smoke are limited in its interior, which limited the extent of the fire outwardthe assured protection of the occupying East and the safety of the teams of relief is taken into account.

In the case of fire safety, the directive covers all aspects of resistance and reaction to fire of materials and structures, facilities and means of detection, and suppression and evacuation routes.

This requirement has been developed primarily through what is known as interpretative documents in a number of fields related to the various aspects of fire safety. Technically the interpretative documents have been covered by various technical committees of CEN (European Committee for Standardization), whose works have been reflected in the publication of a series of rules and of projects of European standards (in and prEN).

To achieve a greater degree of unification, CEN and ISO (International Organization for Standardization) reached an agreement, known as the Vienna agreement, so that both agencies coordinate their activities and to work twice or go in different directions.

The solution

In reality, the solution of the euro-class provides the identification of those existing European test methods or under development to enable the development of a database such that can begin the negotiations in the field of products. It must be borne in mind that, once elected the test methods, must be three degrees of freedom for political considerations:

- The number of classes, related to one or more of the intended use (coating, clothed of slabs, walls, facades, etc.).

- The weighting of the fundamental parameters: flammability, flame spread, amount of unselfish heat, etc.

- National regulations will unilaterally decide that kind of product can be used, depending on the constructive configuration and use.

The euro-class

This decision establishes initially two main sections:

- Materials of construction, to the exclusion of soils

- Materials for soils

The first includes the following elements:

- Products for walls and ceilings, including their surface coverings.

- Construction elements

- Products incorporated into the interior of the building components

- Pipes and piping components

- Products for facades/walls

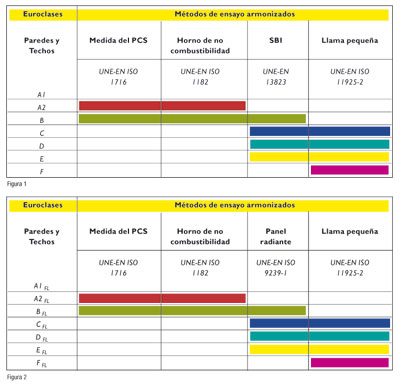

The planned euro-class are seven: A1, A2, B, C, D, E and F.

The second group refers to soils, including their surface coverings, and the euro-class are also seven: A1FL, A2FL, BFL, CFL, DFL, EFL, and FFL.

Focusing on the first group, of more general application, the required characteristics to each class shall be:

- Euroclase F. Without certain behavior. Materials for reaction to fire characteristics have not been specified or that can not be classified in any of the other classes.

- Euroclase e. reaction to acceptable fire. Products able to resist attack by a small flame for a brief period of time unless there is a substantial spread of it.

- Euroclase D. contribution to acceptable fire. Products that meet the requirements of the class and that are able to resist the attack of a flame small unless there is a substantial spread of flame and with limited production of drops on fire during a longer time period,. In addition, to be submitted to the SBI test, they must submit:

- a time to turn on sufficiently long,

- a propagation of the flame, heat and smoke production limited, detachment and

- a reduced production of drops and/or burning particles.

- Euroclase C. contribution to fire limited. As the D class, but meeting more restrictive requirements.

- Euroclase B. contribution to the fire very limited. Products that comply with requirements which are considered to be more restricted than those of the class C. Moreover, in a fully developed fire conditions, these products will not increase significantly the thermal load of the enclosure and the development of the fire.

- Euro-class A1y A2. No contribution to fire. The products of the classes A1 and A2 will not contribute to fire at any stage of the same, including a full-featured burning: for this reason it is considered that they are capable of automatically comply with the requirements of the other classes.

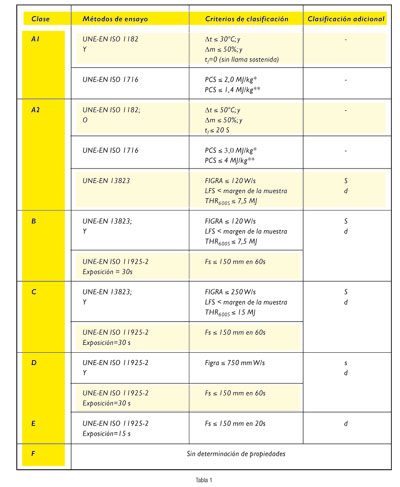

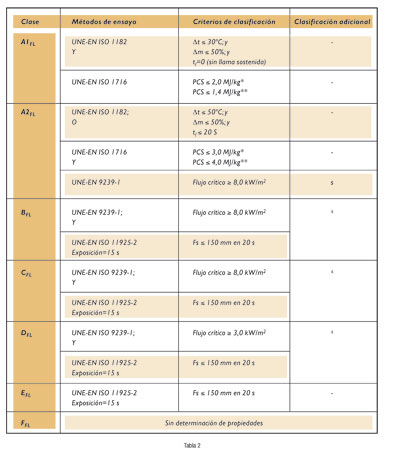

For each of the classes, the acceptance criteria are those shown in the tables. These criteria are derived from the experiences in the performance of the products during a fire, taking into account the conditions of end use.

* the classification of opacity of fumes is not related to the possible toxic nature of the same

Trials

In this way have been selected four test methods to assess the reaction to fire of the construction products, in order to respond to these three levels of thermal solicitation and knowing that three of these four methods existed and were already standardized.

Considering also the soils and their coatings, it must be added a method of testing more, also existing.

These testing standards (see figures 1 and 2) as usual do not include classification criteria, so they should be established at European level, and this reflected in the relevant parties and the new standard EN 13501 tables.

Classification based on the behavior against the fire of construction and products obtained in reaction to fire tests. UNE-EN 13501-1.

- Part 1: Classification based on the data obtained in reaction to fire tests.

- Part 2: Classification based on the data obtained in tests of resistance to heat (excluding products used in ventilation systems).

- Part 3: Classification based on the data obtained in tests of resistance to the fire in the products used in normal service facilities of a building (other than smoke control systems)

- Part 4: Classification based on the data obtained in tests of reaction to fire in smoke control systems components.

- Part 5: Classification based on the data obtained in coverings exposed to external fire test.

The objective of this standard is to define a procedure harmonised for the classification of the reaction to fire of building products and has been prepared as a support of the second essential requirement of the directive on construction products in the European Community (89/106/EEC) and as detailed in the document interpretative issue 2: Security in case of fire (twelve C62, vol 37).

The classification criteria and employed symbols, with their definitions, can see in tables 1 and 2, below.

Materials for walls and ceilings

- Principle: The purpose of this test is to identify those products that will not contribute, or at least significantly to fire regardless of their final use.

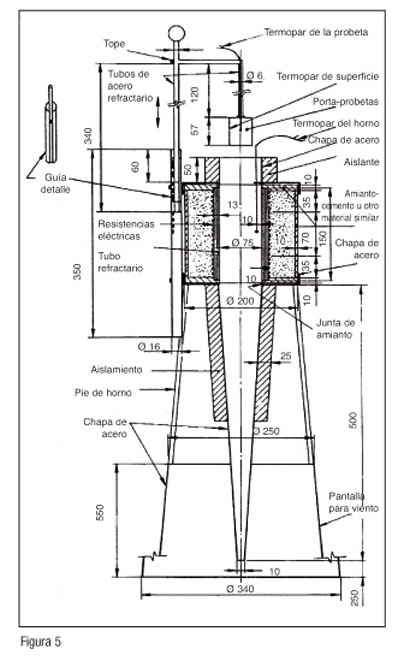

- Apparatus: The trial is done by the apparatus whose scheme is presented in Figure 5, and consists essentially of:

- a refractory tube surrounded by electrical resistance heating and insulation-this set constitutes the actual oven),

- a diffuser of air base and an open top screen of the tube

- a portaprobetas equipped with a device suitable for download and upload the test tubes by the axis of the tube.

- a thermocouple in the oven

- a temperature logger

- Samples: Try a test of cylindrical tube (diameter: 45 mm, height 50 mm)

- Procedure: The test involves placing a test tube in the portaprobetas, which is suspended from an adjustable tube, allowing its descent to the interior of the cylindrical furnace. This is heated by an electrical resistance, getting inside a temperature of 750 ° C in continuous mode during the twenty minutes of duration of the trial. In these circumstances, the specimen is subjected to a level of exposure exceeding the 60 kW/m2.

During the time that the basket portaprobetas remains in the interior of the oven, the temperature indicated by the thermocouple is recorded.

- Specific parameters:

-DT: Increase in temperature (° K)

-tf: duration of flame sustained (s)

-Dm: Loss of mass (%)

- Reference standards: this standard corresponds

with ISO 1182: 2002.

- Principle: The purpose of this test is to determine maximum heat of a product production when burned completely, regardless of their final use.

The higher calorific power of materials which individual part of a product is determined separately.

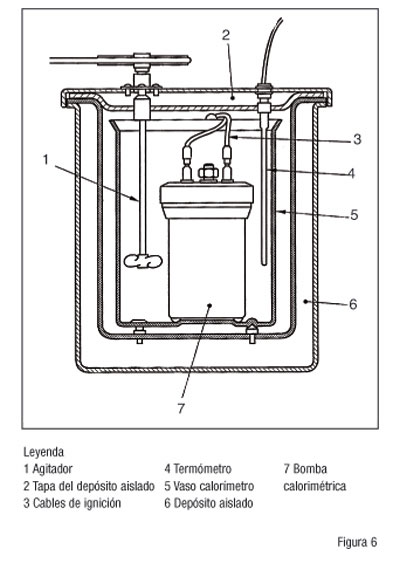

- Apparatus: The test is performed using a calorimetric bomb, whose outline can be seen in Figure 6.

- Calibration: By combustion of 0,5 g of acid benzóico.

- Sample: 0.5 g of material in the form of homogeneous mass (powdered or crushed).

- Procedure: The indicated weight of the material to be tested is placed inside the combustion chamber of the pump, heating under pressure and in an atmosphere of pure oxygen by means of an electrical resistance until it burns. The elevation of the temperature of the water surrounding the combustion chamber can determine, by means of a formula simple mathematics, the heat of combustion of the material.

- Specific parameter:

The result is expressed as PCS (power Calorífico Superior), such as amount of energy released per unit weight (d) the test piece; This is what is usually known as its "thermal burden" in kcal/kg or kJ/kg. The PCS of a product is calculated to give birth to the PCs of their constituents.

- Reference standards: this standard corresponds to ISO 1716: 2002.

The two described trials are the classic problem of non-homogeneous materials (composites, multi-layer, coated or laminated).

As you can see in table 1, the A1 class materials will be tested by both methods. Reference to the class A2, in the above table appears written a "or" no longer clear the issue, now that the four parameters obtained from both methods: calorific power with the calorimetric bomb and increase in temperature, length of sustained fire and loss of mass in the oventhey cannot be compared.

The European Commission has prepared a list of products which, under specified conditions, can be considered as belonging to the A1 Euroclase without need for testing. This information is given in the decision of the Commission on 4 October 1996, laying down the list of products belonging to the euro-class A1 and A1FL "no contribution to fire" provided for in decision 96/603/EEC

These products are those containing less than 1% of organic matter (by weight or by volume) and their combinations for gluing (with queues that do not exceed 0.1% of the total by weight or by volume).

Construction products exposed to thermal attack caused by a single object on fire UNE-EN 13823

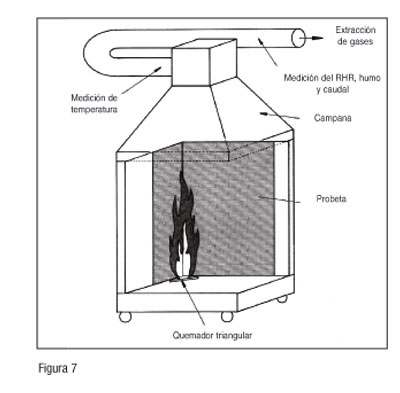

- Principle: The SBI (Single Burning Item, translated as "unique object on fire") is a new test method. It is designed to assess the potential contribution of a product of construction to the development of the fire. Stop this, looks like that the material to be tested is in a room next door to the fire and is attacked with a medium level of exposure.

- Apparatus: The material is placed in a configuration of corner, with a height of 1.5 m and two walls: one of 1 width and another 0.5 m of width.

The sample does not include roof or third wall and is mounted on a chassis portaprobetas of steel, designed to test test tubes of different thicknesses, to 0.2 m.

The portaprobetas also enables testing test tubes in position of roof and is designed so that the exposed surfaces are placed always exactly the same distance from the source of ignition.

The chassis is also designed to allow the fall of drops, or pieces of the product that is burned, in its lower part.

- Sample: Two plates of material: 1.5 m x 1 m and 1.5 m x 0.5 m.

- Procedure: Figure 7 shows the basic layout of the trial. The test tube, mounted in the portaprobetas is placed directly under a Bell in which smoke extract mechanically.

The test lasts about 30 minutes.

Initially it is working with gas with open flame burners (box) that can obtain the profile required flow, but at the same time you are looking for a source of radiant heat as alternate or simultaneous heating element.

- Specific parameters:

-Fire behavior

-HRR: Detachment of heat

-THR: Total detachment of heat (MJ)

-FIGRA: Index of growth of the fire (W/s)

-LFS: Lateral spread of the flames

- Behaviour of the production of smoke

-MMR: Detachment of smoke

-TSP: Total production of smoke (m2)

-SMOGRA: Index of growth of the

production of smoke (m2/s2)

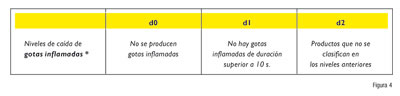

- Behaviour in aspects of falling drops or particles

-Fall or not of drops and/or swollen particles.

- Reference standards: there is No. It is a new test developed by a group Ad Hoc of the CEN/TC 127.

Flammability of the construction products when they undergo the direct action of the flame. Test with a single flame source. UNE-EN ISO 11925-2.

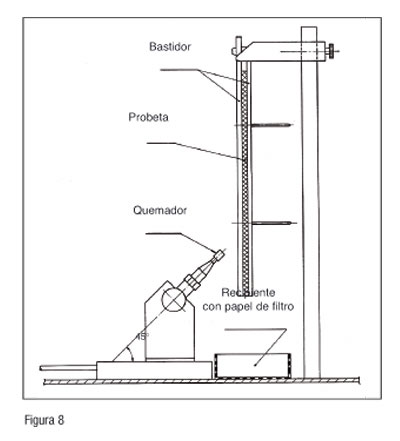

- Principle: This essay tries to discover the features of the products in a situation of fire representing the attack from a small fire on a limited area of these products, what is simulated by means of a small burner with a length of limited flame.

The purpose of this essay is to evaluate the ease of ignition of a product subject to the presentation of a small flame of 20 mm in height. The exposure times are 15 or 30 seconds.

The test is similar to the Kleinbrenner (small burner) of the standard DIN 4102 Teil 1, currently used for the German classification B2...

- Sample: Test tubes of 250 x 90 x e (e £ 60 mm).

- Procedure: The test is performed in a metal Chamber, inside which the speed of the air shall be comprised between 0.6 and 0.8 m/s. The test tubes are placed vertically in a portaprobetas of stainless steel in the form of U (Figure 8). To the test tube are two brands with yarn of cotton which are used to determine the speed of propagation on its surface.

The source of ignition is composed of a burner, a fine and fueled by propane gas adjustment valve. The burner attacks the test tube at an angle of 45 °.

- Specific parameters

FS: Vertical spread of the flames (if the top of the flame reaches 150 mm on the point of application).

-For the end uses where relevant: drop drops and/or swollen particles (if l ignition of filter paper).

Materials for soils and its coatings

That same test for materials of walls and ceilings (UNE-EN ISO 1182 and 1716) will be used for classes A1FL and A2FL.

Determination of the behavior to the fire by a radiant heat source. UNE-EN ISO 9239-1 14.

-Principle: This paper describes a procedure to evaluate fire behavior, and optionally the production of smoke, floor coverings placed horizontally in a test Chamber when exposed to an environment of regulated radiant heat energy and glows a pilot flame. Applied radiant heat flux simulating a level of thermal radiation similar to the one that appears in the floors of a building whose upper surfaces are heated by flame or hot gases, or both, from a fire fully developed in a room or area adjacent.

The results reflect the characteristics of the whole of the

tested floor coating. Modifications on the reverse, the paste or the substrate or other changes in the system can affect the results of the trial.

The Group Ad Hoc 3 of CEN/TC 127 (CEN/TC 127 AHG3) entitled "Floor coverings" has prepared a draft European standard based on the ISO/DIS 9239.2 for these materials, "Fire testing - Reaction to Fire - Horizontal Surface Spread of Flame on Floor Coverings using a Radiant heat source ignition". It is very similar to ASTM E 648, formerly known as NBSIR 75-950 and that it is now used for the German classification B1 for lining of soil. This will be the main European trial for soils and their coatings.

-Sample: Six test tubes 1050 x 230 mm. Three test tubes in each direction shall be tested.

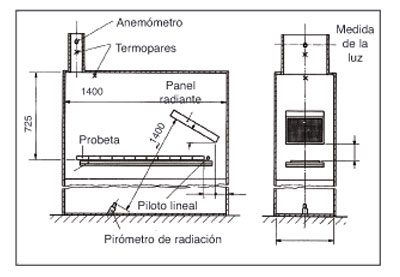

-Procedure: The test tubes are placed horizontally inside a test (Figure 9) Chamber and subjected to the action of a powered by a mixture radiant heat panel gas-aire, tilted 30 degrees on the test tube, and its lower part, 140 mm of it.

The radiant panel is porous refractory material; its measurements are 300 x 450 mm, and provides superior to 815 ° C temperatures, with such characteristics, the level of radiation on the specimen varies between 1.1 and 0.1 W/cm2. In one short of the test tube end there is a linear burner gas, consisting of a steel tube of 10 mm in diameter and 250 mm in length, with perforations. The maximum duration of the test is 30 minutes.

- Specific parameters

-CHF: (KW/m2) critical heat flux

-For the end uses where relevant: smoke density

The same trial that for materials of walls and ceilings (UNE-EN ISO 11925-2) will be used for classes DFL, EFL, BFL and CFL.

Baseline scenario

The norm UNE-EN 13501-1 defines the scenario of fire as "the detailed description, including the environmental conditions, one or more stages before of the swelling until after complete combustion in a place specified or a simulation to scale".

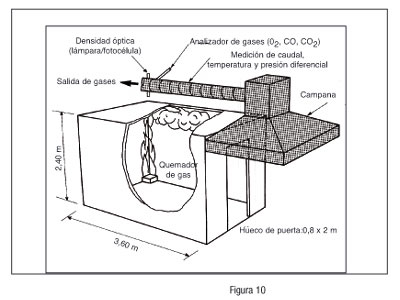

The essay in corner, called "Room corner test" and it is made according to the standard ISO 9705, and the parameter "Flash-Over" (widespread fire) are the base that they support the new European classification system for construction products. They correspond to the scene of fire of reference across Europe, which has allowed to determine the known limits of the euro-class.

Thus, States that:

The construction-products classified A1, A2 and B are the most secure products in the field of reaction to fire and do not contribute to the phenomenon of "Flash - Over".

Products of building C, D and E are more dangerous products in the field of reaction to fire and contribute to the phenomenon of the "Flash-Over" in a short period of time more or less.

The norm UNE-EN 13501-1 defines the "Flash-Over" as "the transition to a State of total involvement of the surface in a fire of combustible material within an enclosure". The phenomenon of "Flash-over" corresponds to a level of fire in the stage of development of the fire. It is the critical point of the evolution of a fire.

This phenomenon that can be described as explosive and devastating occurs to swell the hot gases accumulated in the premises, which causes a deflagration and a brutal increase in the temperature reached values ranging between 500 and 1000 ° C.

To understand this phenomenon is necessary to imagine that a fire is started locally (for example in a trash can or a sofa...); Once that has been developed sufficiently to attack the surrounding materials (carpet, curtains...); the contribution increasingly important heat load in the room, associated with a regular intake of air, causes a brutal increase in temperature and a widespread inflammation of all materials and fuel products.

The European reference scenario

The trial of the "Room Corner Test" is carried out in an enclosure with the dimensions of a small room, and measures especially the emergence of the "Flash-Over" and the time in which it occurs; allows you to assess, in operational circumstances closer to those that occur in case of fire, the behavior to the fire of the products. In other words, the amount of energy and emitted smoke.

The conditions of the source of ignition (time, temperature) have been obtained from the modelling of an object which ignites in a corner of the room: the burner releases firepower of 100

Classification criteria

Preparation of samples and trials

The test tubes are acondicionarán prior to the test at a temperature of 23± 2 ° C and a relative humidity of 50 ± 5% until a constant weight.

He is considered that a test-tube has reached a constant weight when two successive, made heavy with an interval of 24 hours, do not differ more than 0.1% of the last weight of the test piece or 0,1 g irrespective of greater weight.

Pretreatment

The initial agreement is that only the floor coverings shall receive treatment of washing and cleaning prior to be tested, materials/products used in this guidance are subject to such procedures in its end use.

Concerning coverings of walls and ceilings, the conclusion is that generally, not be clean as the soil and the redecoration is more likely.