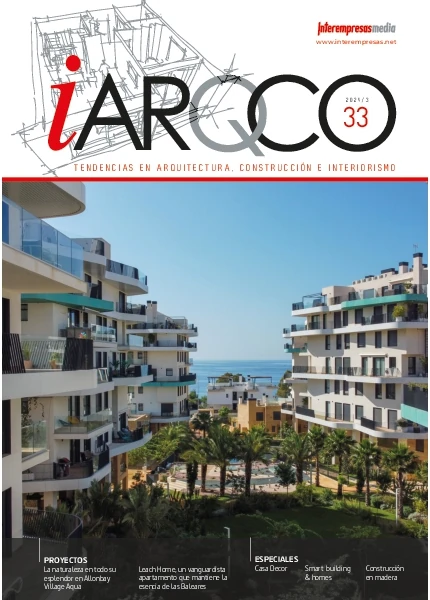

Edition of transition from the fair which is maintained as an international forum in the composites sector

• Conferences on different industrial sectors major users of composite materials

• Presentation of innovative solutions based on composites through the awards "innovation awards"

• Thematic areas devoted to the presentation of demonstrators representing applications of interest in different sectors.

• Commercial presentations

• Demonstrations of different processes and technologies "live and live".

Figures

The intended surface has been of 36,500 square metres (opposite the 35,500 square meters in 2005), and they have gathered in her 900 exhibitors, equal to the 2005 figure.

On the other hand, is still appreciating a growing presence of originating in Asia, mainly China and India companies.

Parallel activities

In this edition of 2006, forums or conferences have focused mainly in the transport sectors (naval, terrestrial, aeronautical and automotive), although other sectors such as construction and natural fibres, have also had presence.

It is included, then a summary of the exposed conferences, as well as the most relevant conclusions of the same.

The sectoral conferences offered, have been the following.

Naval Forum

• "Analysis of interlaminar fracture toughness of Woven 3D composite reinforcements in Marine Structures using finite element models". Ensieta (Fr.)

• "Do Higher technology laminates and structures are light enough - but are they tough enough?". VT Halmatic (UK)

• "Influences on the mechanical properties of multi-axial warp Knitted fabrics". Donghua University, College of Textile (China)

• "Design and Production of a large warship radome using advanced analysis techniques and out of autoclave processing". Lola Composites (UK); Lola Group (UK)

• "Improvements in the commercial viability of Finite Element Analysis for accurate engineering of marine structures". High Modulus (UK); Matrix Applied Computing (UK)

• "Do New breakthroughs in performance for the America's Cup sailing Class?". Protis value - Univ. of the Méditerranée (FR); K Challenge (FR)

• Use of the method of finite elements in the prediction of the failure of the material by peeling or fracture interlaminar.

• The use of techniques of FEM for optimization design of components.

• The importance of the stiffness and toughness of laminates and structures in the shipbuilding sector. Specifications of testing materials composed and comparative results between different materials impact. It emphasizes in conclusion, the interest of the use of sandwich structures and Lightweight monolithic arrays, because his behavior to impact is similar to that of traditional laminates and panels of high thickness. This offers the possibility of weight reduction without compromising behavior to impact, and the tenacity of the materials.

• Viability of manufacturing with sheet of low temperature (without need to autoclave) components of good mechanical behavior (comparable to those obtained by autoclave) and with a lower cost.

• The use of the information technologies (sensing, networks of communication, etc) in conjunction with composites.

Land transport Forum

• "An embedding of tram and subway rail system are segmented polyester supports with continuous concrete foundation". Ars Creatiae Ltd. (Croatia)

• "Use of renewable materials for smc bus component". Faserinstitüt Bremen e.v..-Fibre (DE)

• "Lightweighting for mass transit applications". Newrail (UK)

• "New self extinguishing PTFE-based fabric combines fire safety with weight savings". Daikin America (USA)

• "Antigrafitti gelcoats: composites as a tonic against vandalism". Groupe Mäder (FR); GTI Process (FR)

• "SkyBus coach design". Kineco Gropu (IND)

Below the main conclusions drawn from these conferences:

• New applications of polyester resins which have proved their technical feasibility in foundations for sleepers and Rails of railroad tracks.

• Applications in SCM, based on thermosetting resins of vegetable origin, offering the possibility of manufacturing of technical components with environmental benefits.

• As for weight reduction, for example proved that a resolute in GFRP cabin can be up to 25% lighter than a determined steel.

• You have tissues of PTFE as an interesting solution from the point of view of cost and performance to the fire, smoke reduction, toxicity and volatile.

• Presents solutions for paintings, gel-coats and adhesive films anti-graffiti based on epoxy, PU and acrylic resins as vandalism solutions of interest to the sector.

Aviation Forum

• "Opportunities to improve performance and reduce weight of composite structures". Stanford University (USA); National University of Singapore (sgp); The Boeing Company (USA)

• "Dassaults Systèmes Composites Part Design to manufacturing Solution". Dassault Systemes (FR)

• "Minimization of design and process risks for CFRP - Innovations by networking in the CRP-Valley Stade". CRP-Valley Stade E.V. (DE)

• "Development of RTM leading edge". EADS Casa (SP)

• "Microwave assisted composite processing". DLR (DE)

• "Future developments and needs of composites for helicopters". Eurocopter Deutschland GmbH (DE)

This sector also shows the relative and growing importance of the use of simulation techniques through the use of tools of finite elements (FEM) for the study, prediction and characterization of the mechanical behaviour of structures and components in composite. On the other hand, are also emerging techniques such as the curing of composites by microwave, and offers a growing importance of the RTM process.

As most relevant key findings arising from these conferences, it should be noted the following:

• The use of simulation tools (FEM) for the prediction of the behaviour of structures and their characterization against failure, mainly fatigue and catastrophic rupture mechanisms.

• There is the RTM as a competitive technology (alternative to the autoclave) for new developments in aircraft, offering a high level of integration, as well as a competitive structural behavior for certain applications.

• Ensures the curing of composites by microwave end properties of the material equal to those obtained by curing traditional, even with significantly shorter cycles. The technology presents as main challenges or obstacles to save its implementation at the industrial level.

• Illustrates the use of composites significantly in helicopters, with the major challenge of increasing automation in the manufacture of such structures.

Construction forum

• "Composite analysis under random and cyclic - fatigue loading". Alpha Star Corporation (USA); The Boeing Company (USA)

• "Basalt fibre reinforcements for composites". Ahlstrom Glassfibre OY (end)

• "high performance grp pipe solutions for Chemical, oil and gas transport". Owens Corning (USA)

• "To FRP piping infrastructure". Amiantit Fiberglass Ind. Ltd. (SAU)

• "Use of composites plates for the rehabilitation of the sewages systems". Lamti/IUT of Béthune-Civil Engineering Dept. (FR); Structure and Rehabilitation; Sika France (FR)

• "Bridge over the River Boyne-Composite enclosure". Fiberforce Composites Ltd (UK)

The main conclusions drawn from the conferences of this sector are listed below.

• Stresses the use of composites for applications in the construction of bridges and the monitoring of the structural health through fiber-optic sensors embedded in the material.

• Use of fibers of basalt as an alternative to traditional glass and carbon, offering high mechanical properties, as well as interesting properties of chemical resistance and high working temperatures (up to 980 ° c on time and 700 ° C in continuous). They are also compatible with common resins, such as polyester, vinylester, epoxy, phenolic, acrylic, etc.

Natural fibres Forum

• "Global outlooks on natural fibres". Atoutveille (FR)

• "Production of natural fibers composites: difficulties and solutions". AFT Plasturgie (FR)

• "Analysis of flax/epoxy using plies tensile behaviour." "Relation between the fibers end plies properties". Université De Bretagne Sud (FR); Help-Dehondt Technologies (FR)

• "Dry impregnation process". Fibroline (FR)

• "Products made of renewable resources: state of the art and future prospects". Invent GmbH (DE)

• "Prospective design contributing to WPC development". IDA (FR)

As for the main findings of the conferences offered in this forum, fit highlight the following:

• It is necessary to increase awareness of natural fibres, mainly in the end users.

• Expected a growth of around 10 percent in the composites reinforced with natural fibers in the next 3 years.

• The incompatibility of natural fibers with many of the polymer is still one of the main difficulties these fibres have, considering the development of polymers that are adapted to these fibers as well as one of the challenges in the short term.

• Degradation with temperature and moisture content are the major pitfalls that arise with natural fibers. The strong point remains its biodegradability.

• Products developed from the use of this type of fiber include: for interior finish of railroad storage with flame retarders, Interior panels of all types of vehicles, etc.

• The main challenges for the future are the following: manufacture of complex components and larger; development of compatibility between fibers and polymers; procurement of thermal and acoustic insulation; improvement of fire behavior.

Automotive forum

• "Enabling design innovation for emerging composite manufacturing processes". VISTAGY, Inc. (USA)

• "Composite space frame technology". ATR Engineering (IT)

• "Development of low-density thermoplastic composites for internal applications with improved structural and acoustical performance". Owens Corning (USA)

• "Volume production of Class A automotive body panels from CFRP". Lola Composites (UK)

• "Lead free coloured gel-coats in automotive applications." Büfa Reaktionsharze GmbH & Co. KG (DE)

• "New developments in powder priming of SMC". General Motors R & D Center (USA)

It can be noted, by way of summary, that existing applications are focused on the development of components for bodywork or interior in long series production vehicles, while addressing solutions for chassis or CFRP structure for competition and high-end vehicles. In this sense, is observed the importance of the processes of resin infusion and RTM in the above-mentioned structural applications composites thermoplastics, as it also notes its growing presence at the fair, found a niche of ever-increasing applicationfor the development of components for interior or hidden body elements.

The main aspects of the presentations of this forum are as follows:

• It is increasing the use of tools for simulation and design, mainly for the simulation of the manufacturing, development of patterns of reinforcement, adaptability of the same, etc.

• Series short and competition vehicles raises solutions in composite chassis. Series of high-volume applications the main objective of market lies in indoor applications, seats, body, etc.

• In high performance vehicles, series production of structures or composite chassis are found around the 5000 units/year. In this context, manufacturing technologies are currently focused on the RTM and its different variants (VARTM, etc), with an additional cost to aluminum structures of approximately 2% in the price of the vehicle.

• Manufacturing in CFRP of body panels, by certain specialized companies, with an approximate volume of 12,000 panels per year, through processes of infusion in CFRP tools are tackling.

Awards. Award-winning innovations

• Caddy of electric golf course, developed by Schappe Techniques, made of sheet of thermoplastic resin (TPFL), using the technique of molding Inflation Bladder (BIM). Truck introduced electric motorization, is completely foldable, presents a low weight, a time of short manufacturing cycle compared to the equivalent of thermosetting resin and a greater recyclability.

Prototype's Caddy golf made of thermoplastic resin sheet

• Aarmfoam Inc. (CANADA). Manufacture of composites and foams termoconformables, with leathers of ABS and core of polipropileno. It presents good behaviour to impact, a good degree of reciclabilidad and absence of dissolvent and volatile organic.

• Sticks of electrical distribution, manufactured by RS Technologies (CANADA), in composite, with good provision resistance/weigh, and the consequent reductions in costs of transport, storage and installation.

• Electrical motors manufactured by Control Techniques (UK), with chassis manufactured by SMC, presenting a good relation resistance/cost.

• Concept of aeroplane entirely in CFRP developed by X, And, Z Prototypes (FR). It treats of an aeroplane no tripulado of high efficiency of consumption.

• Demostrador Of “Flap Track” developed by EADS Defence and hygiene Systems (OF). This mechanism moves the flaps rear of the wings during the operations of depegue and landing. Manufactured in CFC, steel and titanium, by means of the technician patented VAP , that does not require of autoclave, presents advantages of reduction of weight, as well as reduction of time of manufacture and setting. This concept finds in phase of consideration for the new To350.

• Inner cylinder or “liner”, manufactured in steel and wrapped in a layer of composite thermoplastic polipropileno/glass injected. It supposes a reduction in weight of until 50% with regard to the cylinders of traditional steel. Manufactured by Amtrol-Alpha Melatomecânica, SA (PT)

• Tube respirador (snorkel) for submarine, manufactured by Eads Defence and hygiene Systems (OF). Manufactured in fibre of glass and carbon also by means of the technology VAP (process patented of infusion of resin without need of autoclave).

Snorkel, manufactured by infusion in fiberglass and carbon

Rail vehicle manufactured in GFRP front

• Development by SNECMA Propulsion Solide's "nozzle" engine of launch vehicles. Weight of only 92 Kg for a structure of 2.5 m in length and diameter 2.1m.

Demonstrations

• Applications of hulls of boats resin infusion

• Machining of composites using techniques of water jet cutting

• Manufacture of preforms fibre of casrbono through specific machinery

• Fast molding of composites by means of electromagnetic induction

Conclusions and remarkable aspects of the fair

As far as applications and sectors is concerned, as set out in the current edition could summarize in the following points:

• The aeronautical sector remains the sector of greater primacy in the use of composite materials, followed by applications for sport utility vehicles and sporting goods, shipbuilding, wind sector, etc.

Vehicle of team Renault Formula 1 of the year 2005

Materials

• It has been observed, as main difference from previous editions, a large presence of developments of thermoplastic composites, mainly thermoplastic CFRP.

• As in the previous edition, observed the presence of various solutions of products to improve the performance to the fire and high temperatures. It's different solutions which include:

• Basaltic fiber

• Gel-coats intumescent

• Retardant additives

• Resins of high temperatures of work, such as Bismaleimidas and Poliimidas.

• Veils of fire protection.

• Other features that one can distinguish the fair of this edition is by the presence of the bio-composites and reinforcements of natural fibres. Conferences, both at different stands, its presence reflects an increase in their impact to previous editions.

• There is the presence of various solutions of materials with good properties of toughness and resistance to impact, in general for applications of parts with energy absorbers function.

Highlights, in this sense, the combinations with rubber and aramid fibres.

With regard to manufacturing processes, include the following:

• In parallel with the presence of thermoplastic composites, there are processes of transformation of these materials, such as compression, stamping, molding with Aperture, moulding with inflatables, etc.

• As was noted in the previous edition, also in the present are shown a number of developments around the resin infusion process, with regard to raw materials (fibers, kernel, resins) and tooling for molds.

• Highlighted, both in sectoral conferences and at the fair, the presence of alternatives to the autoclave technology, both for its implementation in the aviation sector as in others, such as the naval.

• Following the trend marked in the previous edition, there is a significant presence of manufacturers of preforms, in their different technologies such as braiding, fiber placement, stitching, etc.

She preforms made by braiding technique and moulded by RTM

• It also highlights the interest in the alternative technologies of curing by induction, microwaves, etc.

Finally, indicate that the next edition of the JEC fair in Paris, will take place on 3,4 and 5 April 2007.