Mosnic-Irudex, S.L. - Filtros autolimpiantes

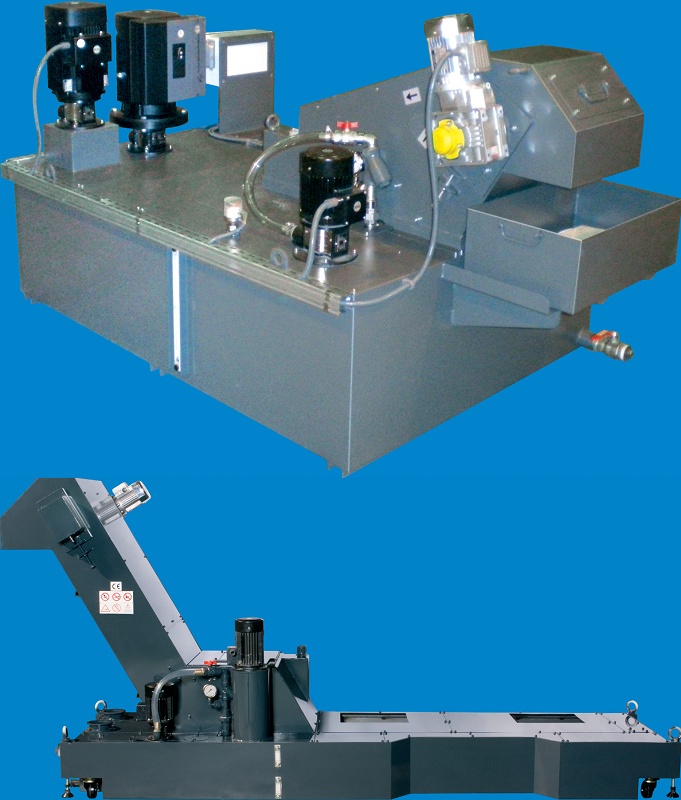

Mosnic - Irudex RDII, RDIII, RC

Filtros de tambor: autolimpiables para filtración final o primaria

Filtro de tambor rotativo autolimpiable, con extractor de virutas incorporado, apto para tratar tanto virutas magnetizables como no magnetizables, y virutas de un tamaño pequeño ó mediano. El medio filtrante empleado varía dependiendo del grado de filtración requerido.

Para el tratamiento de partículas magnetizables y no magnetizables generadas en los procesos de mecanizado.

Por mediación del tambor cilíndrico montado en el interior y empleando una malla filtrante adecuada a las especificaciones de grado de filtración requeridas, se consigue una eficaz limpieza de emulsiones, aceites de corte y detergentes de lavado.

Consiste en un tambor rotativo acoplado a un transportador de rascadores.

El tambor autolimpiable se encarga de filtrar el líquido sucio (líquido refrigerante+partículas metálicas) por medio de la malla filtrante, mientras que las partículas metálicas van a parar al fondo del filtro donde son evacuadas por medio de los rascadores.

Se llega a obtener una muy buena claridad de filtración: 30-50 micras al 90%.

El tambor está perfectamente sellado de manera que el líquido sucio solo pueda acceder al interior del mismo a través de la malla filtrante.

El tambor es una unidad independiente que se adapta al equipo extractor de virutas, lo que facilita las labores de mantenimiento, ya que en el caso que sea necesario extraerlo se extrae todo el tambor en un bloque.

Posibilidad de filtrar un amplio rango de caudales.

Los equipos RDII, RDIII y MD se emplean para filtrar caudales pequeños y medianos y los RC para grandes caudales.

Poseen una buena adaptabilidad a los distintos tipos de aplicaciones.

Posibilidad de procesar tanto viruta imantable como no imantable.

Añadiendo en el fondo del filtro una cama de imanes mejoramos las prestaciones del equipo en cuanto al procesado de partículas magnetizables se refiere.

Para el tratamiento de partículas magnetizables y no magnetizables generadas en los procesos de mecanizado.

Por mediación del tambor cilíndrico montado en el interior y empleando una malla filtrante adecuada a las especificaciones de grado de filtración requeridas, se consigue una eficaz limpieza de emulsiones, aceites de corte y detergentes de lavado.

Consiste en un tambor rotativo acoplado a un transportador de rascadores.

El tambor autolimpiable se encarga de filtrar el líquido sucio (líquido refrigerante+partículas metálicas) por medio de la malla filtrante, mientras que las partículas metálicas van a parar al fondo del filtro donde son evacuadas por medio de los rascadores.

Se llega a obtener una muy buena claridad de filtración: 30-50 micras al 90%.

El tambor está perfectamente sellado de manera que el líquido sucio solo pueda acceder al interior del mismo a través de la malla filtrante.

El tambor es una unidad independiente que se adapta al equipo extractor de virutas, lo que facilita las labores de mantenimiento, ya que en el caso que sea necesario extraerlo se extrae todo el tambor en un bloque.

Posibilidad de filtrar un amplio rango de caudales.

Los equipos RDII, RDIII y MD se emplean para filtrar caudales pequeños y medianos y los RC para grandes caudales.

Poseen una buena adaptabilidad a los distintos tipos de aplicaciones.

Posibilidad de procesar tanto viruta imantable como no imantable.

Añadiendo en el fondo del filtro una cama de imanes mejoramos las prestaciones del equipo en cuanto al procesado de partículas magnetizables se refiere.