Pipes TOM of PVC Oriented: Efficiency and energetic saving

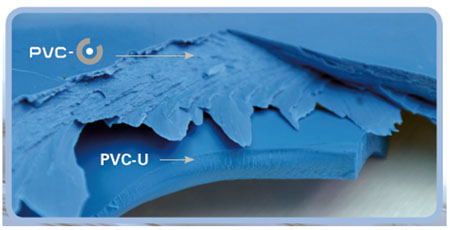

The pipes of PVC Oriented (PVC-Or) are manufactured by means of a process of conventional and back extrusion orientation molecular. The basic tube extruido, under some determinate conditions of temperature and pressesure, is subjected to an estiramiento that produces in the interior of the pipe a structure laminar, that improves of significant form the mechanical properties of the product at the same time that keeps intact his chemical properties.

At the same time that it produces this improvement of properties, takes place a decrease of the thickness of the wall of the tube, like this, with less quantity of prime matter, achieve tubes of better provision, obtaining an optimisation of the resources of raw materials. This lower consumption of raw materials, translates in saving of power during the extraction equipment equipment of the same and the production of the material.

It is necessary to take into account also, that the new process of manufacture of the pipe TOM, patented to world-wide level, possesses a big energetic efficiency, since it requires a lot of lower quantity of power that the necessary for the production of drivings of other materials, and even that other processes of manufacture of tubes of PVC-Or. The process Molecor besides, only consumes electrical power, with what deletes the most important contribution to the effect invernadero by the broadcast of CO2 owed to the use of fuels, minimising the effect on the climatic change of the planet.

To these energetic advantages, it is necessary to add that, because of the automation of the process Molecor, reduces the hand-held quantity of necessary work for the production and achieves a greater productivity that in other productive processes.

Efficiency during the use

The useful life of a pipe for the transport of water is quite long, considers a period of 50 years for his study, but could give a quite upper data if they take into account the perfect state in that they find plastic pipes that have been buried a lot of more years. This useful life, begins in the moment of the construction of the network with the installation of the pipe.

In this regard of the efficiency and the energetic saving that takes place during this stage, can differentiate several appearances:

• Optimisation of the transport

Thanks to the lower weight of the pipe, because of the lower thickness of the wall, can transport more quantity of material, therefore have saving of fuel and minimisation of the broadcasts of CO2

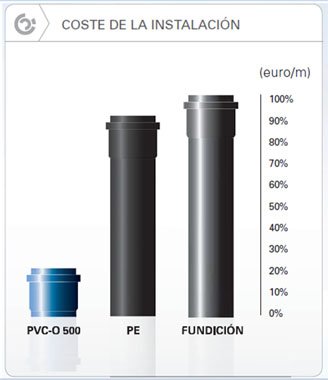

• Efficiency in costs of installation

or Also because of his lower weight, needs less hand of work and machinery for his installation

or The effective design of the glass designed in the tube TOM, allows that the tubes are assembled with big ease

Joining these two factors obtains a performance of installation very high, reducing of considerable form the times of execution of the works with the consequent saving.

Taking into account also that the cost of the pipe offers competitive advantages when it is compared with other materials, the total cost of the driving can see reduced more than 50%, according to the material and the diameters to install, with the consequent optimisation of economic resources that they can be allocated to the construction of new installations.

• Efficiency during the operation

The pipes of PVC-Or present a greater hydraulics capacity, of until 40%, with what for a same energetic consumption, the quantity of water transported in elder.

This increase of hydraulics capacity has to by a part, to the greater internal section that presents the driving when reducing the thickness of wall during the molecular orientation. On the other hand, the lower rugosidad of the material does that the internal surface of the tube was extremely smooth, with what minimise the losses of load and the fluid can circulate to greater speed.

In the useful life of a system of pipes, the parameter that more contributes to the consumption of power, is the necessary power to realise the pumping. In the case of the pipes of PVC-Or, according to the study ‘Estimate of the energetic consumption and of the broadcast of CO2 associated to the production, use and final disposal of pipes of PVC, PEHD, PP, Smelting and Concrete' realised by the Polytechnical University of Catalonia, obtains the best behaviour so much in the lower energetic consumption (825 KWh), as in the lower broadcast of CO2 (363 kg) to the atmosphere, by what his contribution to the effect invernadero is lower. All this, does that the pipes of PCV-Or are the most ecological solution because of his best contribution to the correct sustainable development of the planet.

• High useful life

The structure laminar obtained during the process of molecular orientation that takes place in the moment of the manufacture, confers to the pipes of PVC-Or a significant improvement of his mechanical properties, resulting a canalisation with a big resistance to the impact and to external loads, as well as a very high resistance to the propagation of the cracks to the interior of the tube

Thanks to these excellent mechanical properties, the pipe is very resistant and remains inalterada during years, with what minimise of significant form, the replacements of pipes damaged or deteriorated in the network with the consequent saving of human and economic resources.

Efficiency in the gestión of waste

The PVC is a material 100% recyclable that can be reutilizado after his recycling, mostly mechanical, in the manufacture of other plastic applications, like the coating of cables or the production of downpipes for evacuation, where the technical requests demanded to the prime matter are lower.

Of this form, reduces the consumption of raw materials virgins and also the volume of the waste generated.

Optimisation of resources hídricos

The networks of supply of water manufactured with traditional materials, register at present, a high percentage of escapes of the water piped, had to so much to the fault of estanqueidad of the unions, as to the breaks produced by the deterioration of the tubes. In a lot of cases, this carries to that the channelling have to be replaced few years after being installed.

The pipes TOM present like the best solution for the conservation of the resources hídricos available during generations. The parameters that contribute are:

• The complete estanqueidad of the unions thanks to the elastic board of high quality used and to the effective design of the glasses, that avoid the escapes of the water piped

• The chemical inertia of the PVC that does that the pipes remain inalteradas during all his useful life. Of this form:

or does not be necessary to concern by the nature of the floor where go to be buried the pipes

or do not need coatings of protection, neither external neither inner

or The pipe is not affected by the corrosion, with what avoids the cession of oxides and metals to the water, that in case of drinkable water, can arrive to suppose a problem of public health if they surpass the parameters of quality demanded for the water of human consumption.

Or Has big resistance to the chemical products, like desinfectantes or phytosanitary ware products, used in the distinct sectors

or does not produce the chemical deterioration of the wall of the tube, that in other materials can ocasionar holes that allow the introduction of external agents in the discharge of the water transported causing his pollution.