This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Aspectos analíticos y tecnológicos del proceso de punzonado de chapa (1ª parte)Equipment and technologies for sheetmetal

Analytical and technological aspects of the process of punching of sheet metal (part 1)

Mateos, S.; Rico, J.C.; Cuesta, And.; Valiño, G.

Department of Engineering of Manufacture. University of Oviedo

15/03/2002

1. INTRODUCTION

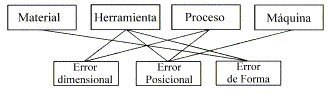

Processes of forming of sheet metal in general, and in particular the punching process, often associated with relatively simple mechanical processes of reduced technological contribution and added value. However, the reality is very different and that these processes, as well as other processes of mechanical type, are heavily influenced by many different factors related to the machine, tools, material and geometrical characteristics of the piece or the environment of the process (table 1).

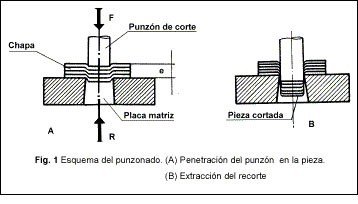

The punching is a cut of plates or sheets, usually cold, by means of a mechanical device consisting of two tools: the punch and matrix. The application of a force of compression on the awl requires it to penetrate the plate, creating a deformation initial system elastoplástico followed by a shearing and breakage of material for rapid propagation of cracks between the edges of cut of the punch and matrix. The process ends with the expulsion of the cut piece (Figure 1).

Fig. 1 Outline of the punching (A) penetration of the punch in the piece

In general, most of the studies carried out on the mechanics of plastic deformation and cutting process, are intended to analyze the defects that occur on the edge of the punzonadas pieces. The first results of the studies on the mechanisms of court in punching occur at the beginning of the fifties, in Germany (Keller) and Japan (Fukui and Maeda) simultaneously. Today, the studies focus on the acquisition of mathematical models along with the finite element method to the calculation of the forces, determine quality of the edge of the piece and the simulation of the process.

Table 1. Different factors involved in the punching.

2. ANALYSIS OF THE PROCESS OF PUNCHING

2.1 Mechanical cutting

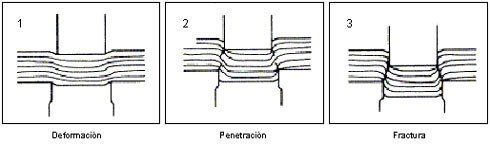

Three stages (Figure 2) can be considered in the process of punching:

- Deformation: the efforts of the punzón on the metallic sheet, originate in this a deformation, initially elastic and afterwards plastic, around the edges of the punzón and matrix.

- Penetration: the edges of cutting of the punzón and matrix penetrate inside the material, producing cracks in the material because of the concentration of tensions along the edges of cutting.

- Fracture: the cracks originated to one and another side of the sheet find , originating the separation of the material. Likewise, the punzón continues his descent to expel the cut. The game of cut J, allows the penetration of the punzón in the matrix (figure 3) and the expulsion of the material cut.

Fig. 2 Stages of the punching

The game of court J has an important effect on the process of cutting and is defined as the lateral distance between the edge of the punch and the edge of the matrix. In general, the value of the game in court is usually expressed in two ways, either as a percentage on the thickness of the sheet and (on court game) or giving the value of the distance between the edges. In the case of hallmarks of circular section, court game will be half of the difference of diameters of the punch and matrix, although it is frequent to find data from manufacturers concerning the difference of diameters of the matrix and punch (2J).

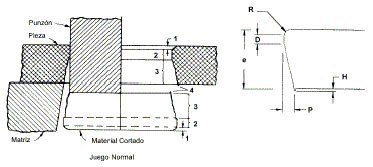

Cutting punching produced several features on the edges of the sheet and cut material. These features are (Figure 3):

- plastic Deformation characterised by a small radius R.

- Zone burnished of brilliant appearance characterised by the width D.

- angular Fracture, with matt appearance, defined by the penetration P.

- Rebaba characterised by his height H.

Fig. 3. Characteristics of the normal game cutting edge

All these features cutting edge depends on the type, hardness and thickness of the material, game between punch and matrix, State of the edges of cutting, clamping of material and size of the punch in relation to the thickness of the steel. The dimensions of zone 2 (Figure 3) determined the punch, in the case of the sheet, or the matrix, in the case of the cut material.

The extension of the 1 plastically deformed zone along with burnished 2 area, are represented as a percentage of the thickness of the material and define the distance traveled by the punch before the fracture of the material. The percentage of the penetration of the punch varies with the type and hardness of the material. Thus, to increase the hardness of the material, the rate of penetration of the awl decreases. On the other hand, the penetration of the awl increases when the punch size is smaller than 1.5 times the thickness of the steel, due to the high effort of compression to the material in the cutting area is subject.

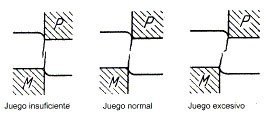

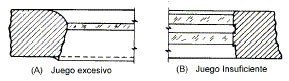

The angular fracture and the quality of the Court depend on the game between matrix and punch. With inadequate clearance between punch and matrix, there is a secondary Court. Corresponding to the punch and matrix initial cracks are not aligned, and therefore fail to find it (Figure 4). The decline continued in the awl produces the prolongation of the cracks and surface not cut between them will be broken in a secondary fracture. In the lower part of the career of the awl, is a secondary Court and a second burnished area (Figure 5-B). The decline of the game, below the normal values, leads to the decrease of all the defects of shape, therefore, to improve the accuracy of the obtained edges.

Fig. 4. Relative position of cracks according to the game

When the used game is too low are starting to appear side cuts that hurt the quality of the edges. It should be noted, that to decrease the game's Court there is an improvement in the accuracy of the piece, however, other factors such as the wear of tools and energy consumed are affected negatively. In the case of gaming of excessive Court (Figure 5-A) appears excessive plastic deformation, a smaller burnished part and a height of greater Burr. On the other hand, must be stressed, he is achieved by increasing the game's cut above normal values, increase the life of the tool to the detriment of the precision obtained at the edges. The game of appropriate court will thus be one that does not cause a secondary Court and have a plastic deformation and height of small Burr.

Fig. 5. Characteristics of the edge with excessive and insufficient game

From the point of view of the material fracture mechanics, can be considered that the functioning of the process is optimal when the cracks initiated from the punch and matrix are aligned. Since that Court is the parameter which most directly affects the material fracture mechanics, the game of optimal cutting must be capable of providing this alignment.

2.2 Forces in the punching

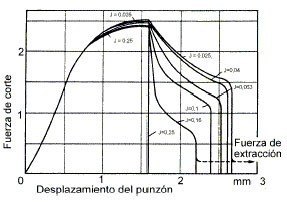

The cutting force varies depending on the game by keeping the other parameters constant. Figure 6, represents the force exerted by a punch of 10 mm in diameter and their displacement to cut a sheet steel of 2.8 mm thick, with different sets of court. In general, curves can be broken down into two distinct parts: the first in which the force increases from zero to its maximum value, point it to the start of the fracture, and a second in which cracks grow and complete cutting of the material. The first area is very similar in all the curves, however, from the moment that begins the fracture, develop significant fluctuations for various games.

Fig. 6 Influence of the game of court J on the cutting force

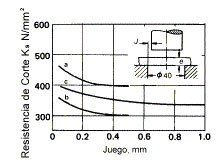

Fig. 7.- Resistance of cut by punzonado according to the game.

To) sr= 630N/mm2, and= 5mm;

b) sr=450 N/mm2, and=5mm;

c) sr=460 N/mm2, and=10mm

The formation of the rift can be associated with sudden downturns seen in the diagrams. When coming out of cracks are not aligned, the steep descent tend to soften, sometimes reaching the horizontal position. In these cases, it tends to produce again important reductions in force due to the formation of secondary cuts. As fluctuations in the reduction of the force, there is an increase of the area enclosed by the diagram, and therefore the energy consumed in the process. For this reason, when in the cutting of sheet metal cracks present the same line-up, the energy consumed by the process is minimal.

Resistance of cutting punching ks shall, from the maximum strength of court Fs Max:

where is the area calculated from the thickness of the steel and and the lp of court perimeter:

and ks includes the effects of the game Court, wear of the tool and the influence of other parameters, such as the properties of the material, thickness and shape of the shape of the punch.

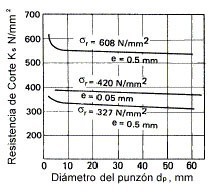

The resistance to cutting by punching ks decreases with the increase in the Court game, being his variation of approximately 14% in the range of J = 0.01 ¸ 0, 1e. Figure 7 you can see this effect, using three different materials and perfectly sharp punches. As carried out fest, the awl suffers wear which is an increase of ks up 1.6 times. On the other hand, the resistance of court is affected by the diameter of the hole punching, so the value of the cutting resistance decreases with the increase in the diameter of the punch if hold other constant conditions (Figure 8). Another factor of influence, is the shape of the section of the awl. In areas of large curvature, there is a concentration of tensions, reason by which it is most frequent rupture of the punch in the angled corners.

Fig. 8. Effect of the diameter of the punch in the punching resistance

In practice, industry estimates the value of ks through shear tB maximum tension, and the maximum by cutting force:

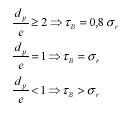

The value of tB it obtains of tables or from the resistance to the break sr. Generally, it takes like resistance of shearing tB an equal value to 80% of the resistance of break, however, this proportion varies with the type and thickness of the material.

According to studies made by Oehler, there is a linear dependency between the shear resistance and the logarithm of the ratio dp/e. According to these studies:

Once cut the material, he should be expelled through the matrix, which in general has taper to facilitate the extraction and hinder the return of the material cut with the back of the punch. The force required must overcome friction and radial compression between the punch and the plate and the cut piece and the matrix. Part of these forces are also present during the retreat of the punch due to the friction of the sheet with the punch. This extraction force is usually expressed as a percentage of the force necessary for the punching and depends on the material and the game of court.

Another factor to take into account, is the State of the awl. So for example, the gradual clogging suffered by the latter originates an increase of the strength of court, and at the same time a reduction of the recoil force.

The cutting speed also has influence over the cutting force. Thus, to increase the speed, reduces the strength, mainly due to the rise in the temperature of the material that originates with the increase in the speed of deformation.

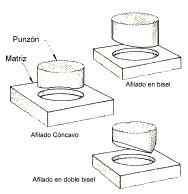

Fig. 9. Special sharp of the awl

When shear forces are too high, these can be reduced considerably using a punching by progressive Court, that is, tilting the cutting of the awl (Figure 9). However, the variation of force is not a variation of the power consumed in the process.

2.3. Wear of the tool

The tool, during his work, is subject to a series of mechanical, thermal, and chemical, actions that have an effect of wear, and is therefore of great interest to know the factors that affect it. These factors include the working material, the number of fest, the material of the tool, the diameter of the awl, court game and lubrication.

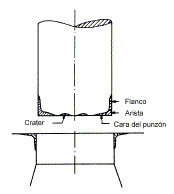

All the mechanisms of wear (accession, abrasion, etc.) can occur when performing operations of punching, both the hallmarks and the airfoils matrix of the sheet to shearing. Wear occurs in three areas: faces, flanks, and edges of the punch and matrix (Figure 10).

Edges of the punch and matrix and the flanks are exposed to the action of generated in the process of cutting surfaces, and the relative sliding causes phenomena of accession in the flanks and edges.

Fig. 10. Wear of the punch and matrix

The punzonada piece undergoes a hardening to the deform plastically, causing growth of local pressures and resulting in the emergence of more abrasive particles. High production speed also gives as a result a large number of impacts, favouring the accession of particles and fatigue of the cutting edges. At the same time, increases the temperature of the matrix, the awl and the piece, for increases it adherence and it favours oxidation.

The elastic deformation of the piece produces a relative motion along the face of the punch, initially towards the outside and later, after the split, inland. This fact produces an abrasive wear on the front face of the punch. The prancing limits this elastic deformation of the material, which reduces wear on the awl. On the other hand, the elastic recovery of the steel produces wear of the flank of the punch in the retraction movement.

On the lateral surface of the punch and matrix, wear is mainly due to the mechanism of accession. Another area that suffers from wear and tear, is the edge of the Court, which presents both wear mechanisms, not being noticeable the influence of the type of material of the tool on it.

The criteria of uselessness of the tool commonly used, are as follows:

- energetic Consumption and necessary maximum strength in the process.

- maximum Height tolerable of the rebaba generated in the cut.

- Measurement of the wear of the faces, flanks and edges in the punzón and matrix.

- Measure of the increase of the game of cut like consequence of the wear.

Fig. 11 Factors affecting punzonadas parts geometric defects

It seems logical to establish models of equations of life, as in the operations of machining swarf removal, allowing know in advance the number of cushionings which is capable of performing a joint punzón-matriz, before being rejected. These models allow to establish the length of the tool before reaching a value of certain wear, which will be function of the chosen optimisation criterion (minimum cost, maximum production, quality, etc.). Studies on this subject are relatively scarce, especially because of the complexity of the mechanism of wear, closely linked with the life of the tool. Therefore, it is difficult to establish models on a large database of experimental.

2.4 Precision of parts punzonadas

The punching, and any other process manufacturing, necessary to establish precise specifications needed to meet the needs of the user. Therefore, it is interesting to do a study of the precision, in order to be able to define these specifications, in the most accurate way possible.

The accuracy of the punzonadas pieces can be characterized by the following defects: dimensional, form and positional. The factors that affect these defects are mainly the material, tools, variations in the process and the machine. In Figure 11 are represented the different factors that affect each of these defects.

The cuts and the hole diameters measured on the polished surface, must match in theory with the punch and matrix respectively. These theoretical dimensions can be altered, due to the influence of some factors, such as the inaccuracy in the dimensions of the tools, the elastic deformations of these or elástico-plásticas tensions produced in the material.

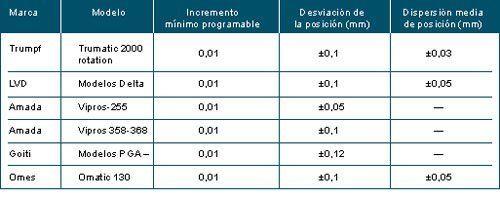

In regards to positional defects, these include two types of geometric inaccuracies: irregularities in the shape of the cut and inaccuracies of the holes of the punched pieces. The first are usually due to the lack of coaxiality between punch and matrix, defects in the guides or the inaccuracy of form of the tools. As for the inaccuracy of position of the holes, it depends on the accuracy of the system of movement of the sheet (table 2).

Shape defects are those that occur at the edges of the piece and depend on the tools and material. Factors of the tools that most affect these geometric inaccuracies, are the game's Court, the shape of the punch and the State of wear of the Ridge, while material, are the quality, resistance and thickness of the steel.

Table 2-the accuracy of various models of punching machines CN data according to catalog

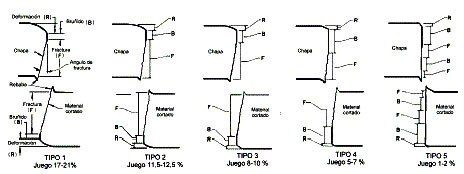

Fig. 12 Different types of edge according to the game. Material steel of low carbon content

Table 3-Approximate range of values of the different edges of the figure 12

Defects of shape can be controlled by adjusting the Court game. Thus, according to the Court game, five types of edges in the plate punzonada can be obtained. In Figure 12 can see schematically for the punching of steel of low carbon content. The characteristics of each of these types of edges can be seen in table 3.

In regards to the dimensions of the hole, they are affected by the change of the game's Court. When using Court games that produce edges as type 4 (Figure 13), the diameter of the hole is about 0.01 mm smaller than the diameter of the awl. However, if you get an edge of the type 2, the diameter of the hole is 0.01 mm greater than the diameter of the awl.

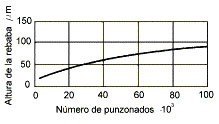

The value of the height of Burr (H) is conditioned, in the case of the cut, by the State of wear of the punch, while in the hole, it depends on the degree of wear of the matrix. Therefore, the height of the Burr depends on the same factors that the wear of tools. Figure 13 shows the height of the Burr on the number of carried out fest.

Fig. 13 Variation of the height of the Burr with the number of strokes