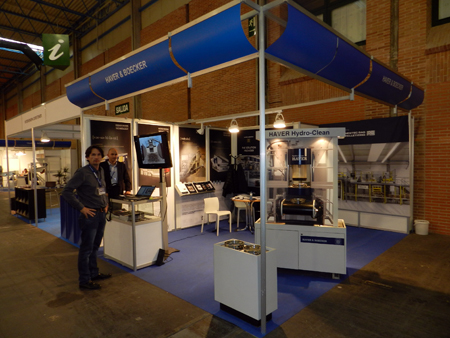

Haver & Boecker Iberian presents in Smopyc 2014 his system Hydro-Clean

Based in a long and wide experience in systems, components and installations of manufacturing of materials,

The result of this technological challenge designates Haver Hydro-Clean and consists in a system of cleaning of high pressesure with an estimate of performance from among 50 and 400 tonnes of material processed by hour. It is perfect for the industry of sand and gravel, as well as for the natural stone and the industry of the recycled.

The performances vary according to the content of slime, needing so alone between 0,12 and 0,2 m3 of clean water for desenlodar a tonne of material contaminated with earth or silt, consuming an power of 0,3 to 0,5 kW/h.

The modular construction of the Haver Hydro-Clean ensures the flexible adaptation to the existent specific conditions and allows a fast installation. Can implement the team of wash to an already active plant or supply him a complete solution, adding after the wash sift, stirrers and circuits of water.

The main component of this system is a vertical container in which, once entered the material in the rough, is washed inside the camera by means of streams of high pressesure fixed to a rotary presses head. The operative pressesure of 40 to 200 bars acts acutely on the material and clean the rocky particles of the resistant dirt and breaks the agglomerates, improving the abrasive strengths that arise of the turbulences in the process of cleaning.

The resultant dirty water crosses the plastic protections of the drum installed inside the container of filled, flowing then out of the camera of wash. The sensors of level located to the entrance of material provide exact data to the unit of the PLC, allowing in this way a regulation of the flow of material in the system and ensuring a consistent precision. The remaining material dirt in the particles is cleared by the wash of classification.

Comparing it with other conventional systems hardly exists wear any, thanks to the tool of cleaning by stream of water. The design of easy maintenance of the Haver Hydro-Clean allows an easy exchange of the standard components that are susceptible to the wear.