Brain Logistics, S.L. - Catalysts

Brain

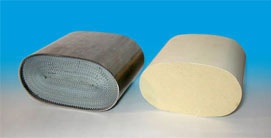

Metal catalysts / ceramic: best thermal conductivity

The catalytic converter is a device capable of removing the pollutants contained in the exhaust of internal combustion engines gas; a filter is not but if a chemical reactor that occur reactions of conversion between gas and precious metals content. The quantity of precious metals depends on the duration of the converter while the effectiveness is tied to its distribution in the substrate.

Brain uses monoliths of high quality certified Euro 4 and guaranteed 36 months. So the reactions cannot be activated it is necessary that the catalyst is heated to 400 ° C; that has to take place in the shortest possible time; a rapid increase in temperature involves chemical thermal constraints and mechanical on the substrate of the converter; that implies the need for resistant, light, little embarrassing and capable large-area substrates. Under this aspect, the metal substrate has many advantages with respect to the ceramic:-better thermal conductivity.

-Heating time.

-Reduced risk of overheating.

-Lower thickness of the walls of the substrate, metallic 0.03 mm, 0.1 mm ceramic.

-More effective surface.

-Possibility of different number of cells, 400 ceramic cpsi, of 25 to 1200 cpsi metal.

-Ability to catalytically superior.

-Smaller dimensions to equal efficiency.

-Greater resistance to shocks.

-High resistance to thermal stress.

-Easier recycling.

Brain uses monoliths of high quality certified Euro 4 and guaranteed 36 months. So the reactions cannot be activated it is necessary that the catalyst is heated to 400 ° C; that has to take place in the shortest possible time; a rapid increase in temperature involves chemical thermal constraints and mechanical on the substrate of the converter; that implies the need for resistant, light, little embarrassing and capable large-area substrates. Under this aspect, the metal substrate has many advantages with respect to the ceramic:-better thermal conductivity.

-Heating time.

-Reduced risk of overheating.

-Lower thickness of the walls of the substrate, metallic 0.03 mm, 0.1 mm ceramic.

-More effective surface.

-Possibility of different number of cells, 400 ceramic cpsi, of 25 to 1200 cpsi metal.

-Ability to catalytically superior.

-Smaller dimensions to equal efficiency.

-Greater resistance to shocks.

-High resistance to thermal stress.

-Easier recycling.