Automation will have a preferential place in the stand of the K 2010 Engel

October 7, 2010

The use of systems that consume little energy is one of the main themes in the presence of Engel in this edition of the K. During the fair you can see a total of 20 machines, 11 of them in their own stand and 9 in stands of companies with which they collaborate.

Automotive

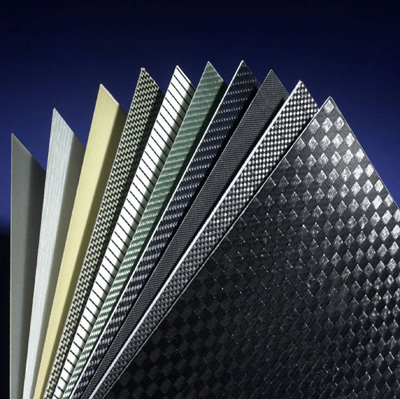

Engel shows an Engel duo 2050/500 peak manufacturing a structural component of a material reinforced with organic plate. Engel will demonstrate this method to produce a piece of the direction made from PA into a cell of complete manufacturing, which includes a complex automation with three robots. This application especially revolutionizes design of light weight because it allows the replacement of steel and aluminum sheet for thin organic films. They contain a special fabric of fibers of glass or carbon embedded with an orientation defined in a thermoplastic matrix of PA or PP. partners in this presentation are Siebenwurst in the construction of the mold and Bond Laminates as material supplier.

It will also display the coating with polyurethane on the injected piece in an Engel e-motion 280 totally electric T which will incorporate clearmelt technology. There is a rear shot of a film that contains a matrix of thermoplastic wood and then covered the piece with a transparent layer of PUR. The process is characterized by a striking 3D visual effect. When compared with a coating of several layers, the main advantages with excellent productivity and the thickness of the layers. Another advantage of the clearmelt process is that the decorative film back injection and in flow with PU coating occur in a single mold without interrupting the process.

The automatic distribution of insert and removal and stacking of the performed pieces performed by an Engel viper 40. Partners in this project are Schöfer (idea of the product and mold) and Hennecke (PUR machine).

On an Engel victory 330/90 tech shows, on the other hand, the processing of solid silicone. The pieces have an approximate diameter of 6 mm, production is automated, require no post treatment and are made in a mold of 64 cavities.

Electronics for telecommunications

Here you will see the new Engel e-insert, an electric version of the machine for inserts, with table swivel servoeléctrica and fully electric injection unit, the closure and the ejectors are operated with the new servohidráulica ecodrive.

An Engel e-insert 310V/100 manufactures casings from PA sensors reinforced with fiberglass with metal in a mold of four cavities. The process includes the sobremoldeo of the Insert cn maximum precision through the electrical injection unit and the maximum speed of rotation with maximum precision in the positioning of the turntable. The process reduces the cycle and improves the costs, while reducing energy expenditure. The automation carried out an Engel viper 20.

Also you can see at the show the production of an electronic component in an electrical machine Engel e-max 200/100. It is a machine which occupies little quick spaces and accurate and has electric injection unit. It is an ideal machine for the production of complex parts for the electronics industry.

Containers and packaging

Two developments are presented for this sector. The new series Engel electric e-cap for the taponería sector provides short courses, high flexibility and low power consumption. This is possible thanks to the new unit of injection, the greater strength of the ejectors and a drive for improved closure. In the K you can see the model e-cap 3940/420 T with a cast of 96 cavities working on a cycle of less than 3 seconds. It incorporates Q-Vision quality control system.

The model e-motion 740 H / 440 M/280 WP, for its part, shows the production of a tube with lid of PP in a four-cavity mould. The tubes are made in the first cycle and plugs in the second, all in a single phase. The machine in the fair also incorporates a system of labelling in mold.

Technical piece

It is the new system of Multitube mould for the production of hollow and complex parts in a single phase. He is achieved through a process of injection of two or more stages that integrates a system of pick & place and the sobremoldeo in a single stage. The main advantage is that it eliminates the need for finishing, as the Union of various components.

It will demonstrate in an Engel victory 1050H/500W/220 combi which produces a piece of two components.

The second machine which is set out in this sector is an Engel 200/50 e-victory, producing a LED from PMMA lens for architectural lighting. The manufacturing cell is optimized for the manufacture of thick-walled optical parts and includes online quality control.

Medical sector

A model Engel e-motion 1340/280 T injected during the fair a piece in a totally automatic process, with an electric machine, with cycles of less than 4.5 seconds in a mold of 8 + 8 - Plastisud/France. The automation is Hekuma.

An Engel victory 330 H/120 combi will produce a valve in two components for the medical industry. It uses a cast of 8 + 8 and is ready for use in clean room.