Manufacture of SD cards in polycarbonate and a step in the technical system at the stand of the K 2010 Billion

Fruit of the collaboration between Polar-Form, the visitors of the K and Billion will know first-hand the manufacture of SD cards of polycarbonate in an electric machine of Billion. The main outstanding points of this machine are the little space it occupies, its precision and energy efficiency, combinads with manufacture in a clean environment.

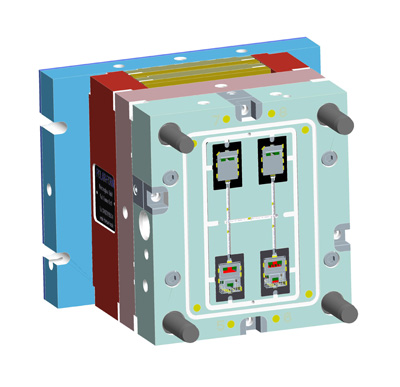

During the contest, the electric fuel transfer from the Select range will be equipped with a spindle of 18 mm of diameter, specially adapted to the PC. The machine produces a mold with refrigerated channels of Polar - Form with two parties (up and down) of an SD card. The injected total weight is 3.7 g. The particular design of the mold allows the separation of the casting of the piece during the maintenance phase, eliminating the need for additional surgery after manufacture. The mold is very compact (296 x 246 x 316 mm) and is then mounted on machines of low tonnage.

A closed in the mold (3 + 3) cooling system ensures the optimization of the cycle in 8 seconds.

Select H80-50T fully electric injection machine.

Mold cavities Polar-Form 2 + 2 SD cards.

A step in the technique of two-component combining rubber and thermoplastics

Billion and Motzener shows the manufacture of a membrane of two components in the K of sealing gas in a cell of Select electricity production in a single process.

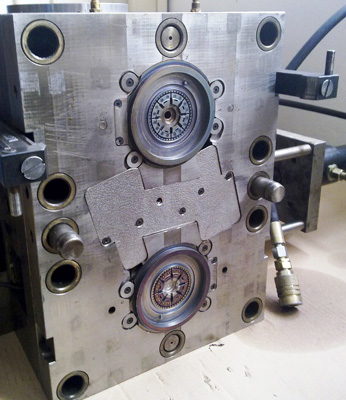

Billion has been developed in cooperation with Motzener Kunststoff - und Gummiverarbeitung an application of rubber / thermoplastic for K. The fuel transfer Billion H150/260-150T take place with a multiinyección process a membrane resistant to ozone gas.

Originally installed in a hydraulic machine, the corresponding template needs to be adapted in order to be implemented in a fuel transfer for a single process. At the same time, all the movements and functions are integrated in the control system.

For this type of pieces of plastics transformers still used two processes. A machine for the manufacture of the body in TP (hard component), then transferred to a machine of rubber for the sobremoldeo and the vulcanization of the elastomer is finally done (soft component).

The Select Billion machine is equipped with units of plasticizing of 3 zones available in standard with a geometry of screw for polyamide (Vestamid of Evonik) and rubber (Kraiburg) components.

Both spindles have a special surface treatment and are protected from abrasion. The 3 areas of Billion rubber spindle maximizes the protection of the material in the cylinder, due to the reduced compression and to less stress in shear. The basic body in PA weighs 3 g, as well as the piece of rubber, with a complete cycle of approximately of 60 seconds. The translation of the piece of plastic with rubber is produced through an indexer dish. Vulcanization of produces in the mold.

A perfect combination of machine and mould

The process is carried out in a fully integrated system, thanks to the control system Dixit 3 of the Select H150/260-150T ensures complete control of several movements. For the mold, the corresponding movements are: vacuum pump, hot channel system, rotating and driver table temperature. The coordination of all the steps can determine and schedule in a transparent manner.