ASCAMM develops the first team of microinjection ultrasonic

April 19, 2010

Currently, microinjection of parts kits are expensive machines that generate a large amount of material of rejection. "The problem is that the same technologies are applied to large pieces to make small pieces," explains Xavier Plantà, innovation director, Ascamm, and head of the new team project.

The solution to the problem

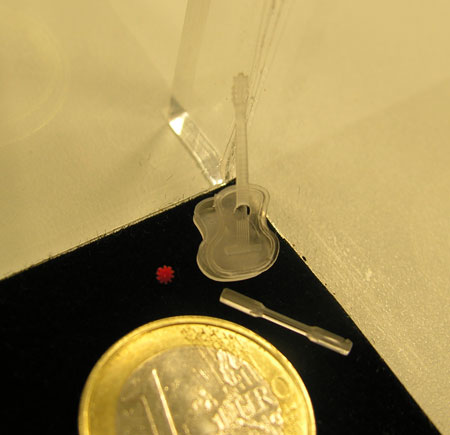

With the machinery which exists in the market, in the manufacture of a gear of 3 millimeters in diameter, that can cost as much as the bumper of a car, generated a great amount of material from rejection. "A problem", pointing Plantà, "in sectors such as electronics and medicine, where the materials are very expensive and 99% of the injection is material of rejection". In addition, this surplus, in sectors such as health, should not be reused because it is biocompatible materials. In the case of other industries that do allow re-use of this excess plastic, Di Manno explains that characteristics and properties of the material lost. In these cases, he adds, "not you must reuse more than 10% of the plastic".

The sector has very specific equipment, mainly of German firms, which can work with microinjection, but require "a high cost of investment". What happens with this type of machinery, argues Plantà, "the cost is so high that very few companies dare to reallizar investment". The most used conventional equipment, but they consume a lot of material. Another added setback is that these machines have a high cost of operation, i.e., consume much since that heated the spindle on a continuous basis. The new team, on the other hand, "only works when it melts". In addition, "consumes very little and inject rapidly," added innovation director, Ascamm.

Technology in operation

The flow of the network with a voltage of 220 or 380 Volt, is transformed into high-voltage current. This alternative stream enters two ceramic pieces in such a way that the electric energy is transformed into mechanical energy in vibration. When it comes into contact with the plastic, heats it and melts it, but does not generate radiation or heat loss, i.e., is heated only what comes in direct contact with the system.

The main technical difficulties of the microinjection ultrasonic, says Di Manno, reside in tightness and getting the material so not cool while the sonotrodo does it vibrate even before it reaches the mould.

The new team of microinjection is a very user-friendly machine, the size of a PC, such as a printer or a photocopy, and easier to use. Any operator can work with it, because before it comes on the market is parametrizarán the maximum number of possible plastic and will be introduced in a database. Thus, "the operator will only have to select the material in a list and the team will do the rest", says Plantà.

The paradox of the team

"In the traditional injection, you warm;" When you warm, you fundes, and when you fundes, inyectas. Our technology fuses but not heated. A paradox! ", explains Plantà." Why? The team, named for the moment as Sonorus, has a sonotrodo moving 70,000 times per second. This arousal creates an energy that makes that the chains of the thermoplastic break. This melts and thereby creates a friction that heats the material and melts it. "When you stop excite, the chains of the thermoplastic solidify again", says Plantà. In the absence of thermal energy, there is no practically contraction. In addition, enough one or two seconds of ultrasound to melt the material, so it is guaranteed a high productivity. Another advantage that stands out the Centre is that on the injection process, the material always loses some of its features. However, "ultrasonic the thermoplastic remains intact".

Ultrasion, a company born in the bosom of Ascamm, composed of technological centers Ascamm and Cetemsa, and companies Mecasonic, Mateu & Solé, Plastiasite and Hoffmann, which aims to develop innovative industrial applications based on the ultrasound has been created for the marketing of the team. Within these applications is microinjection, which shares ownership with the pultrusion and an ambitious project of rapid prototyping, among others. To this end, Ultrasion has a budget of 3.5 million euros over four years, 75% of which comes from private investment.