Contribution of the variable frequency energy saving

"The influence of the variable frequency in the plastic injection machinery is decisive" begins stating Joaquín Moliner. A plastics injection machine is a machine which incorporates an electric motor of a power adequate to the characteristics of the machine. They are usually high powers and it is therefore that any action on these engines will directly impact on energy saving in the overall of the machine.

Difference between variable frequency drive and variable displacement pump

In connection with this matter, j. Miller explains the following: "For years have witnessed how the main builders of machinery opted for variable displacement pumps claiming his improvement of energy consumption." The basic explanation was that the bomb, to provide the minimum flow at rest, exerted no effort on the electric motor. But in the case of the variable frequency equipment can stop the revolution of motor in long cycles, i.e. consumption 0. A machine equipped with variable flow pump may never come to consumption 0, given that the electric motor is always spinning to 1,500 rpm, and we must not forget that is focus of consumption, if you rotate consumed, if not turn does not consume.

Improvements of process with variable frequency

As he goes on to explain, by installing a variable frequency drive into a machine we can see at a glance the decline in electricity consumption. "Virtually we can speak of reactive power consumed 0" says. Other relevant details that can be achieved with the variable frequency drive are as follows: reduction of machinery noise, lower heating oil because only moves the necessary oil for each movement; reduction of surcharges in electric motor; improvement of the life of the oil and reduction of consumption in the cooling of machinery equipment.

Any machine on the market can be adapted to new technologies. "The old drives are today obsolete." The modern equipment give us infinite possibilities of regulation and can achieve amazing results. A good team needs as well as a proper Installer, because a mismanagement of this kind of applications can cause increases in consumption or machinery failures. It is essential to have a wide experience to carry out a proper installation. "From ATI System we offer our collaboration for customers applications and will advise you to the processor indicating machines where the intervention is more profitable, always seeking returns on investment of less than a year."

Reductions in actual application

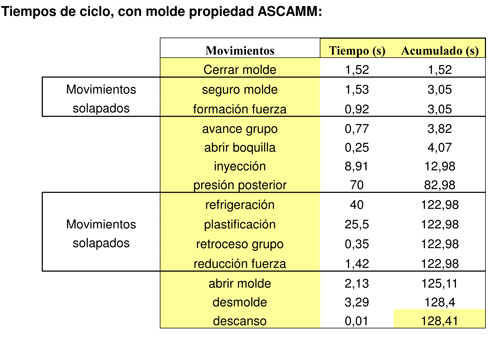

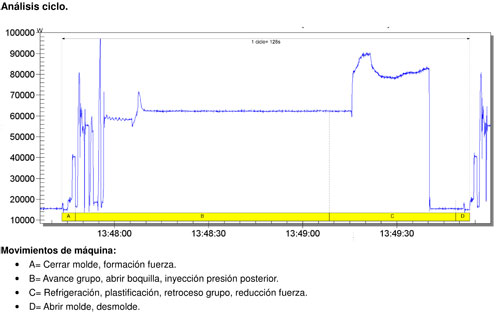

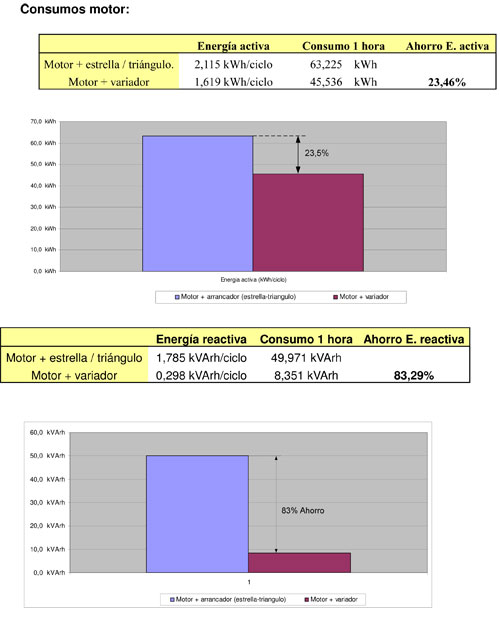

In the two charts that accompany this article you can see the results of an ATI application with a machine of Krauss Maffei.

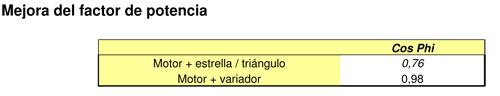

Using the solution proposed by ATI System is obtained a reduction of 23.5% of active energy and an 83.3% of reactive energy. Because of this it has gone from a power factor of 0.78 to 0.98. All this without affecting the cycle time of the piece.

Made speed regulation is dynamic, meaning that the system is suited to machine configuration. If amending the injection times, opening mold, etc. also amending the speed of the engine, achieving a flexible system that does not require any intervention if switching from mold or simply by modifying the configuration of the machine.