Risk of explosion in cabins of dried

Introduction

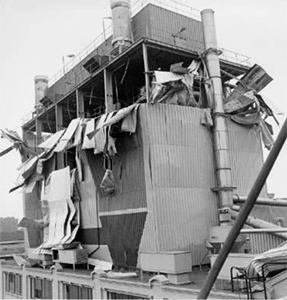

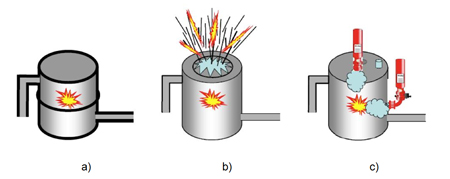

Appears 1. Effect of explosion in a secadero.

The principle of dried by means of pulverización is based in the transformation of liquid in dry dust during an only process of manufacture. The liquid is disintegrated in small drops by means of a rotary presses disk or a filter. The drops go in in contact with the half of dried hot (in the case of alimentary products uses only air) causing a fast evaporation of the present water in the surface. This system allows to use air to high temperature without that this can affect to the product, even if it treats of materials highly sensitive to changes of temperature.

The increase in the superficial temperature of the particles produces only at the end of the process of dried, when the surface is not entirely humid and the drops have almost transformed in dry particles. The time of dried by means of this technology is inferior to the required when they use another type of devices, since it treats of some seconds. When treating of a period of time reduced, is not sufficient to cause damages in the product dried, reason by which this solution is so used in applications of dried in alimentary industry, pharmaceutical or chemical. After the dried, the particles are separated for a processed back.

Properties of the dust generated during the dried

As it has signalled previously, the operation of dried generates materials of which originate the particles of dust. Because of the process, these particles of dust are very susceptible to the learning of spontaneous combustion, fire and explosion.

With the end to warn the apparition of these extraordinary events, is always necessary to know, no only the conditions of operation of each part of the technology of dried in general, but also the parameters of fire and explosion of the effects caused by the dust.

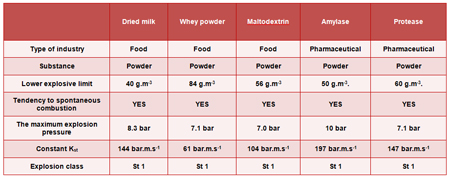

For greater clarity, include in the Table 1 the parameters selected of dust produced that arises during the process of dried.

The table shows values that represent the limits of suitable prevention against explosions. It treats of those necessary values for the suitable construction and systematic design of the protection anti-explosion.

Statistics of dangerous events

In the years sixty of the past 20th century, produced in the installations of production of dried of dust, a big number of accidents, included the fires and explosions.

The detonantes that caused the accident (fire and explosion) include:

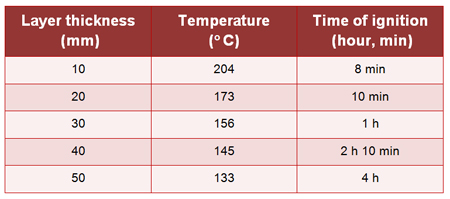

- Car-lit in a layer. Considers quite usual and the most likely cause of a start of explosion, in accordance with different reports realizar. For example, the content of fat in the milk, plays a very important paper inside the temperature of car-ignición. The critical ‘temperature' of car-ignición, diminishes when increasing the content of fat. The conditions of car-ignición determine by the dependency of the critical temperature of car-ignición in the kinetical of release of heat, in the conditions of exchange of heat with the environingingment and in the moment of the action of these factors. This means that under some conditions, can occur a spontaneous warming to temperatures lower of the initials and, on the other hand, in other conditions, the high temperatures can not being dangerous.

- Pollution of the air of admission (entrance) in the room of dried. Is necessary resaltar the importance of the degree of purity of the hot air of entrance in the room of dried. Before proceeding to his introduction, the air has to undo of all the mechanical impurities by means of an effective leak. This is necessary, between other reasons, to obtain a good quality of the product, since the mechanical impurities can carbonizar in the system, and have showed to be the particles of black colour that appear usually in the dry substance. A deficient leak repercute in a product of deficient quality.

- Surfaces of friction. The contact between the mobile parts of the different devices of dried, have been, usually, other elements triggers of explosions. It treats of equipment such like centrifuges atomisers, fans and tourniquets.

- Initiation by an electrical spark. Occurs, among others, on existent fans, when it exists the risk that it deposit a hard layer that arrive to damage or block the álabes. A second possibility is the apparition of sparks been due to the static electricity, or a deficient put to earth of the conductive elements.

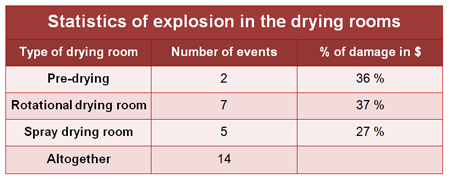

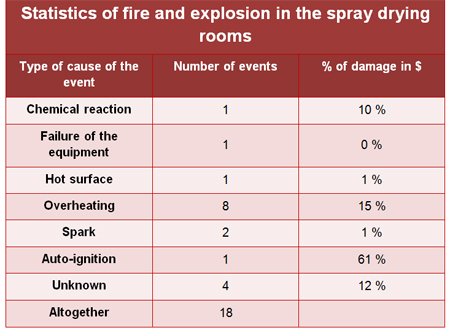

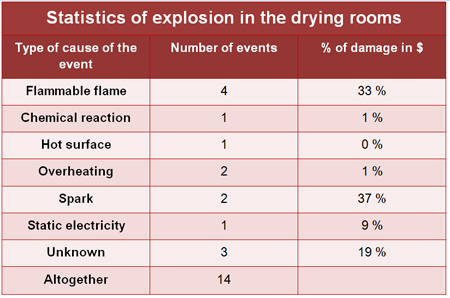

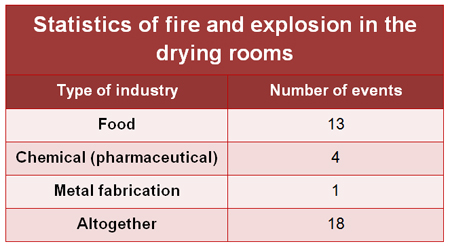

In the following tables enumerate statistical data of the company of insurance (FM Global Insurance Company) on accidents in installations of dried.

Of the statistics presented by this company and the parameters of explosion of dry substances that enumerate in the Table 1, gives off that the risk of fire and explosion can not be subestimado, to the light of the current parameters. Operators and/or manufacturers have to consider include in his installations, all the measures of technical and organisational type to guarantee the hygiene, no only of the people, but also of the installation.

Factors to consider in front of a fire or explosion of material dried in the interior of the devices

The inferior limit of explosividad of the products varies of 10 to 100 g/m3. The

The dimension of the parameters of the explosion are consequence of the concentration and the turbulence of dust. In principle, the pressesure of explosion increases when increasing the concentration until his optimum ‘value'. After surpassing this value, reduces again the pressesure and the dynamics of the explosion. The

If they form in the interior of the dryer layers of dust deposited, that can be agitated and raised of diverse forms, can cause an increase of the concentration that approach to the optimum value (concentration to which attain the highest parameters of explosion). An a lot greater danger that in the own dryer, in terms of the creation of concentration by turbulences, is the one who can generate in devices, such like pipes, cyclones separadores and filters.

The greater danger of an explosion of dust produces during the decrease of the speed of flow and the increase of the temperature of the surroundings. This is used to to be been due to different factors:

- Interruption of the flow of mix dust / air

- Failure of feeding

- Interruption in the supply of liquid product or concentrated

- incomplete Cleaning of the room of dried

- Errors in the process of filtered

- Creation of the layer of dust in the pipes of transport or in the surfaces of the exchanger of heat, etc.

Appear 2 to 4. Photos of explosions in dryers and effects of said explosions.

Danger generated during the operations of filtered

To continuation detail some of the main dangers that can generate:

- Danger of development of sediments of the components filtered

- Danger of overheating

- Danger of car-ignición

- Danger of apparition of sparks (electrical, electroestáticas, by friction)

- Danger of fire

- Danger of explosion.

Basing in parameters of explosividad and fire, the operators have to classify the enclosures and devices in zones, defining the different sources of ignición and a proposal of measures of technical and organisational type. This information has to be collected in the documentation of protection against explosions.

The analyses of risk realizar are used to to involve, usually, no only the application of a series of specific measures, but also technical measures of protection anti-explosions of passive character and/or constructive.

The prevention of passive type includes the following methods:

- Constructive protection

- Release of the explosion combined with a separation of the explosion

- Suppressesion of the explosion in combination with a separation of the explosion

Appear 5. Types of prevention anti-explosion.

The verification of the resistance to the pressesure has to realizar before the application of the elements of anti-explosion in the systems of dried. In the first place, the values of resistance to the pressesure have to verify, as IN 14460, in the documentation of the manufacturer (provider). In case that desconozca said values, has to realizar a practical verification, by means of calculations MKP of the parts of the installation selected.

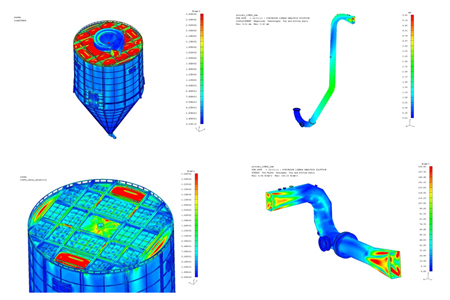

In the Figure 6, presents a graphic example of the calculations, above-mentioned, of the resistance to the pressesure of the camera of the dryer, as well as of the pipes of interconnection between the individual elements.

Appears 6: Example of control and optimisation of the calculations MKP of the parts selected of the dryer.

After verifying the resistance to the pressesure, proceeds with the own installation of the components that form the system anti-explosion.

To continuation, include different images of the main individual elements and equipment of protection anti-explosion.

Appears 7. Application of system of relief of explosion of agreement to IN 14 491 and IN 14 797 in the mantle of the dryer by pulverización with the deflector for the driving of the flame and the pressesure to the outside of the building.

Appears 8. Application of the system of berrera HRD barrier. Instrumented for the separation of the explosion, of agreement to IN 15 089 between the camera of dried and the cyclone of separation.

Appears 9. Installation of equipment for the suppressesion of explosion in accordance with IN 14373 in the cyclone of separation.

Appears 10. Installation of rotary presses feeder under the cyclone of separation as IN 15089.

Appears 11. Application of barrier HRD in accordance with IN 15089 between the cyclone and the filter.

Appear 12 and 13. Application of system of relief in accordance with IN 14491 and IN 14797 in the mantle of the dryer by pulverización with the deflector for the driving of the flame and the pressesure to the outside of the building.

Appears 14. Installation of valve of closing under the units of leak. System of protection anti-explosions as IN 15089.

The system of protection against explosions is connected to a central unit that manages no only the devices of hygiene, but also the mechanical elements, such like valves, feeders, etc. Said unit manages the communication with a system of upper control that commissions of the commandos of course and unemployment of the different elements of the installation.

Conclusion

The subjects of hygiene in front of possible explosions generated in devices of dried by means of the application of passive devices, is turning into a decisive step inside the group of elements of hygiene for the people and the installations. The operators have to consult this area of hygiene to experts or companies that have of sufficient experience in this field and can provide answers, and especially councils. These tecnólogos have like mission direct the requirements of the operator to a system of protection that, in addition to being safe for the workers, was it also for the own installation.

Of the same way, can not shelve the current development of the own devices of dried. The manufacturers have to his disposal a series of legislative instruments to reduce the risk or delete it.