New standards for the productivity in the industries of processes

“The solutions of automation Festo reduce considerably the costs of capital, installation and operative and, therefore, the costs of cycle of life (LCC) of the plants of production. Savings of until 40% in the costs of conventional automation are possible in some cases”, explains Eckhard Roos, responsible of the Management of Processes of Automation Festo. Changing the design of components and systems, the users can prolong the useful life of the installations of production and reduce considerably the number of defective articles. This reduces the costs of the cycle of life of the installations of production and at the same time increases the productivity. The final result for the user is the increase of the competitiveness in his global markets.

For the engineers Festo, the knowledge of the processes of the customer is essential. Understand the technology of production forms part of this. It is precisely this knowledge that allows to the engineers of processes develop some optimum solutions together with the customer and apply them beginning from the phase of basic engineering going through all the back phases, in all the places of production of the customer to world-wide level, through a global network of engineering, production and services.

Systematic automation ...

The basic engineering seats the bases for the optimum automation of a system through the standardisation. In addition to offering advantages to the hour to purchase the components of the system, the standardisation simplifies the global supplies. Also it suits during the phase of operation, since the systems of automation of processes can remain operational until 25 years —much more time that the systems of automation of factories—. To the equal that the saving in the stock of pieces of spare and in the requirements of learning, the standardisation also facilitates the validation of the technology of system. “They can attain more advantages extending this concept from the system to all the plant” continues Roos.

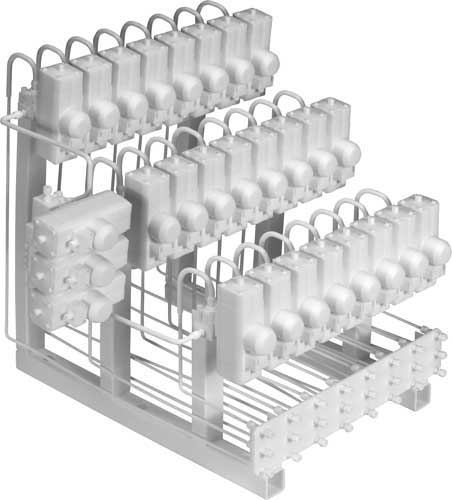

An example of success of standardisation is B. Braun Melsungen AG, the plant of manufacture more modern of Europe for solutions of infusion. Thanks to an exhaustive analysis of the requirements of the technology of automation by experts Festo and B. Braun, all the chain of value benefits enormously of the components of automation standardised. This allowed to the pharmaceutical company increase significantly the availability of the system, attaining a substantial reduction in the costs of maintenance and replacement of the components.

... Along all the chain of value

The greater number of machines and systems along the chain of value, from the systems of mix through the machines of filled, esterilizadores, machines of inspection and envasadoras, had to be instrumented with the same or similar products and solutions of automation. The advantages of this were obvious: lower stock of pieces of spare, lower complexity in the works of maintenance and, the biggest advantage of all, the can treat with same speaker of automation. This last factor accelerated the processes of request and, because of the big quantities involved, generated economies of scale reducing like this the costs of purchase.

Nevertheless, the basic engineering allows a critical look further of the technology of automation. “The optimisation of the components and how are connected mecánicamente has profits, in particular for the multipurpose systems, for example reducing the number of final products lost in processes of wash or cleaning”, explains Roos. An example of this is a system of distribution designed by Festo for his use in the production of articles of aseo.

Complete solution to a problem

The complex network of pipes and racores used in the production of articles of aseo carries to considerable losses of products when changing the production of an article to another. The answer was a complete solution of Festo. Decades of experience in engineering helped to resolve the problem of the customer and increase permanently the productivity of the plant during all the cycle of life of the product.

The solution was a new and compact block distributor of valve of ball for more than 20 deposits used to store several scents. To be able to realizar it of fast and precise form, in the first place manufactured and agreed with the customer a model CAD 3D. To be insurance, Festo also manufactured a model of fast prototype to scale 1:5 before finalising the design. This allowed to realizar some adjust final of the project in query with the customer.

Greater efficiency

The subject of ‘efficiency' is winning increasingly a greater impulse between the operators of plant, already was in the planning of the processes, acquisitions, construction and set up or in the use of the power and other resources.

This does not mean necessarily invest in new plants; the existent plants and how are interconnected can offer an enormous potential of saving. Examples of this are the pumps in plants of waste treatment water or the costs of personnel for the inspection of the basins of retention of water of rain. The technology of modern automation can finish also with the need of investment in the electrical infrastructure of the networks of feeding.

Saving in the electrical installation

Up to now, the electrical actuators were the first option for the plants of treatment of water in Russia –to open and close the entrances and exits of the filters of sandy mulch or in stations of pumping–. In St. Petersburg, the use of only electrical actuators would have meant an installed power of 75 kW. The plant could not supply such power without expanding the electrical infrastructure.

A pneumatics system with actuators DAPS, including two compressesors of air, requires an installed power of only 10 kW. Simply substituting the electrical actuators by 120 pneumatics actuators, the operator of the plants of treatment of water of St. Petersburg was able to save at least 65.000 additional euros that of the contrary would have had to spend in the electrical supply.

Data of production = information

The aim to avoid interruptions in the process of production because of failures is just in the first place of the lists of requests of a lot of users. Combine the products of automation with the functions of diagnostic for the evaluation of data forms the base for this and facilitates besides a programming of maintenance advanced. Nevertheless, the diagnostics do not limit only to the control of the solution of automation Festo.

In fact, the specific evaluations of data can provide information on failures in the complete system. “This is another of the ways with which can increase the availability of the system”, says Roos. These data can be consulted and used in the network of the local system, in the intranet or even to world-wide level road the browsers web.

Summary of the supply of water in real time

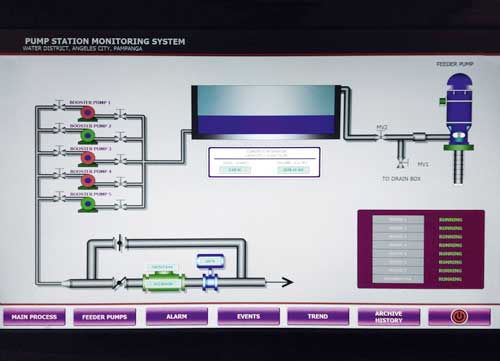

Take like example the Philippines, where a solution of automation Festo has increased the productivity of the water supply for the city of Angels. The technological heart of the system is the communication in real time between the pumps of supply and distribution and the centre of control of process via WLAN. Festo Was manager of all the project, from the development until the acquisition, installation and set up.

Nowadays, all the key information enters in the centre of control of process the 24 hours of the day and offers a precise picture of the water supply in real time. The director of the plant can see the state of the system of a glimpse in the screen and like this take measures if it was necessary, although a system of control entirely automatic means that this only will be necessary in exceptional cases.