Modern technology is cheaper than low benefits

Why are the prices of machines under pressure?

Because of several tendencies and appearances, the prices of purchase of the machines of moldeo by injection have gone down along the years:

- The increasing sensitivity with regard to the prices by part of the transformers of moldeo by injection that operate to world-wide level,

- The concentration of the acquisition that realise the big transformers with a similar structure to a holding and, with this, the selective increase of the volume of determinate requests,

- The inclusion of the departments of purchase in the process of decision of purchase,

- The increasing use of the auctions realised through Internet and

- The “adelgazamiento” of the machines with a minimum volume of equipment.

The status of competition in Europe

Despite the efforts of the European manufacturers of machines address the trends mentioned above with new offerings, the trend towards the segmented and geared to the production purchase offers new possibilities to the so-called "low specs" machines. These are machines with low performance data ("low specifications") that are made by Asian manufacturers and are sold in Europe. Currently, Asian importers have reached in Europe by pieces sold a percentage of 5% of the market. Not yet commercial activities of this type have been detected in Germany. Manufacturer of machines "low specs" focus on the sale of new machines, without offering a comparable variety in terms of after-sales service, development of projects and equipment tailored to the client as the European manufacturers.

What effects are more favourable to the machines "low specs" parameters?

The Demag Plastics Group has made costly series of evidence both with own client's machines, obtaining comparable castings production data to develop a comprehensive cost-benefit analysis. The study was based on factors affecting manufacturing costs and, therefore, in the profitability, i.e.

- The acquisition of the machine (purchase price, technical data of the machine),

- The operation of the machine (cost of servicing and maintenance, power consumption and cooling, availability, cycle time) and

- The resale value of the used machine.

The following considerations are intended to show how the above variables affect cost models.

The purchase price of simple injection molding machines from Asian production is significantly lower than the European machines. With a force of similar closure and similar distances between stringers as main guidance criteria, the average Asian machines acquisition costs totalled only 60% of European technology.

An effect that positively affects the profitability of European machines was not taken into account: the automation. The assessment of the growing automation of injection moulding machines depends largely on the wage level of each country. Due to the large differences, he dispensed in these considerations of a quantification of this effect.

Technical data is contemplated, in particular, distances between stringers, relevant to the production. The corresponding values were used for the factors affecting the operation of the machine, empirical or those values which create a virtually ideal setting for "low specs" machines.

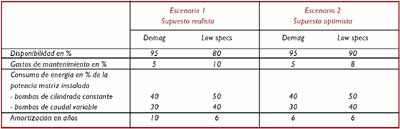

The results shown below are based on the conditions of manufacture of a central European country. The main parameters (excerpt, see table 1) are

- The relationship between the clamping force and the distance between stringers,

- The availability of the machine

- Energy consumption

- The consumption of coolant

- The cycle time and

- Maintenance costs

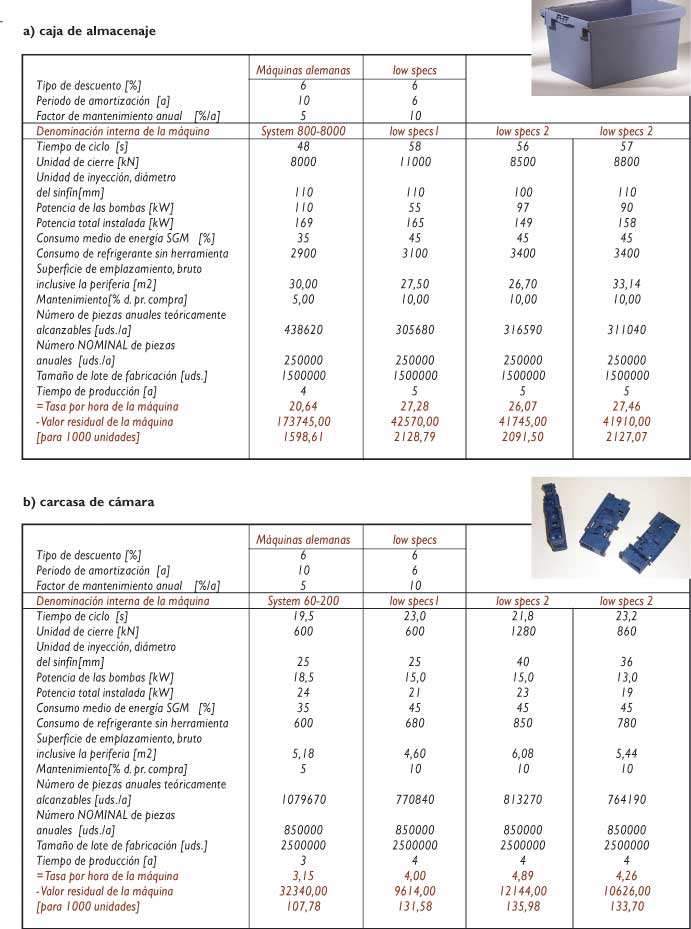

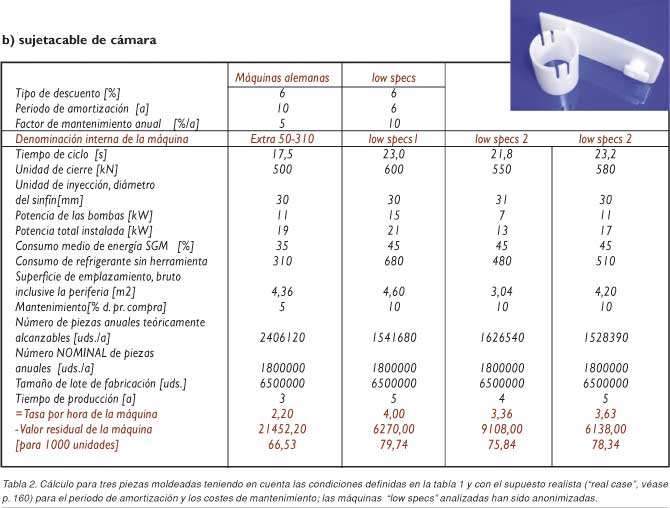

The analysis of the profitability was developed based on different parts - storage box, cover of camera, cord-grip - in terms of size of the molded part, the closing force required and the necessary performance of the machine in two scenarios. Based on the average values available for the factors of influence were determined conditions limit for a "real case" (realistic case) (table 2) and - in the best conditions for machines "low specs" - for a "optimistic case" (case optimistic).

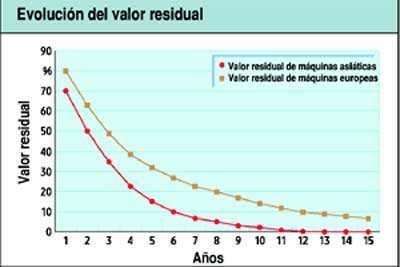

The realistic assumption is based on an amortisation period of six years for "low specs" machines and ten years for European machines, as well as maintenance costs of 10% of the purchase price per year for machines "low specs" and 5 per cent per year for European machines, in addition to the loss of value of the two types of machines.

The optimistic assumption (from the point of view of Asian suppliers) is based on periods of amortization of equal duration of six years and particularly favourable maintenance costs of 8% of the purchase price per year for "low specs" machines andagain, of 5% per year for European machines, as well as the loss of value of the two types of machines. These assumptions are quite optimistic for each of the variables. In short they appear to be unrealistic, but they show the margins can reach Asian suppliers.

Calculation examples

• with equal periods of amortization and maintenance costs are very favorable for machines "low specs", i.e. in the "optimistic case" are lower than a 3% to 22% depending on the piece molded to the manufacturing of machines "low specs" costs (table 3).

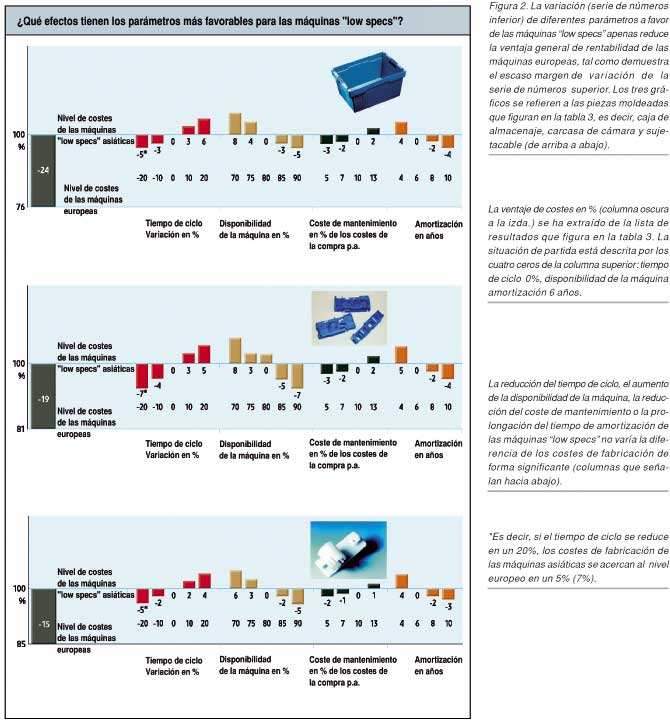

Or the variation of the different parameters of Asian machines has a significant influence on the result. Even a substantial reduction in the time of cycle, a significant increase in the availability of the machine, a reduction in maintenance costs or a lengthening of the amortisation period do not change the result in the Fund (table 2). Only an appreciable simultaneous improvement of all operational parameters can improve the outcome of the machines of Asian origin. However, such improvements cannot be achieved with the technology of the machines "low specs" and, therefore, must be considered unrealistic.

This article was developed based on extensive tests and well-founded assessments. Depending on the location of the production and the molded part manufactured has to repeat the calculation, but this does not change a fact: the European technology of injection molding has its purchase price, but in the production process provides a clear economic advantage. A manufacturing oriented profitability cannot be confined simply to the reduction of the purchase price of a molding machine by injection, but it must control all the factors and determine their impact on the costs to later define the production environment more economically favourable to a piece in particular.

Summary

In the present analysis of the costs of manufacturing of different molded injection parts, the high availability of European machines and its increased performance compared to the "low specs" machines, have proven to be key success criteria. With regard to profitability, the purchase price of the machine plays a secondary role. The economic benefits are independent of each application and independent of the location of the factory.

Despite the little demonstrated influence of the purchase price on the profitability of the production of injection molding, the Demag Plastics Group faces pressure on prices in the acquisition of machines and the demand for cheaper offers as a manufacturer of machines. It contributes, on the one hand, the concept of platform with the decentralized manufacturing and high volume of standard machines with specific equipment and according to local needs. These machines are available in very short delivery times and offer a good relationship cost - performance. On the other hand, the modular system with flexibly configurable machinery technology, offers the right solution for the high demands of transformers. In addition, commercial and large geographical coverage after-sales service structures support customer in situ of a rapid and comprehensive.

Being a manufacturer of machines rooted in Europe and operating worldwide, the Demag Plastics Group wants to emphasise with this study on the cost efficiency of the technology of European machines for production in series.

Central European machines of manufactured injection according to the standards provide an economic advantage on the machines of simple equipment of Asian manufacturers, so-called "low spec" machines to transformers. The cost benefits are independent of specific applications or the site of production. In an analysis of the costs of manufacturing various molded injection parts, the increased availability of European machines and its higher performance have proven to be the decisive criteria that contribute to the success: accredited by studies, manufacturing costs are between 8 and 38% lower than the "low spec" machines. When we talk about profitability, the purchase price of the machine only has a secondary importance.